Investigating Accidents and Incidents:

Purpose:

Every year people are killed or injured at work. Over 40 million working days are lost annually through work-related accidents and illnesses. Recent figures show that an average of 250 employees and self-employed peopleare killed each year as a result of accidents in the workplace.1 A further 150 000 sustain major injuries or injuries that mean they are absent from work for more than three days. Over 2.3 million cases of ill health are caused or made worse by work.

According to the Labour Force Survey, over 40 million working days are lost through work-related injuries and ill health, at a cost to business of £2.5 billion.

The same accidents happen again and again, causing suffering and distress to an ever-widening circle of workers and their families. The investigation and analysis of work-related accidents and incidents forms an essential part of managing health and safety. However, learning the lessons from what you uncover is at the heart of preventing accidents and incidents. Identify what is wrong and take positive steps to put it right. This guide will show you how.

Carrying out your own health and safety investigations will provide you with a deeper understanding of the risks associated with your work activities. Blaming individuals is ultimately fruitless and sustains the myth that accidents and cases of ill health are unavoidable when the opposite is true. Well thought-out risk control measures, combined with adequate supervision, monitoring and effective

management (ie your risk management system) will ensure that your work activities are safe.

An effective investigation requires a methodical, structured approach to information gathering, collation and analysis. The findings of the investigation will form the basis of an action plan to prevent the accident or incident from happening again and for improving your overall management of risk.

language of investigation:

Certain key words and phrases will be used regularly throughout this guide.

‘Adverse event’ includes:

- accident: an event that results in injury or ill health;

- incident:

near miss: an event that, while not causing harm, has the potential to cause injury or ill health. (In this guidance, the term near miss will be taken to include dangerous occurrences);

undesired circumstance: a set of conditions or circumstances that have the potential to cause injury or ill health, eg untrained nurses handling heavy patients.

Dangerous occurrence: one of a number of specific, reportable adverse events, as defined in the Reporting of Injuries, Diseases and Dangerous Occurrences Regulations 1995 (RIDDOR).

Hazard: the potential to cause harm, including ill health and injury; damage to property, plant, products or the environment, production losses or increased liabilities.

Immediate cause: the most obvious reason why an adverse event happens, eg the guard is missing; the employee slips etc. There may be several immediate causes identified in any one adverse event.

fatal: work-related death;

major injury/ill health: (as defined in RIDDOR, Schedule 1), including fractures (other than fingers or toes), amputations, loss of sight, a burn or penetrating injury to the eye, any injury or acute illness resulting in unconsciousness, requiring resuscitation or requiring admittance to hospital for more than 24 hours;

serious injury/ill health: where the person affected is unfit to carry out his or her normal work for more than three consecutive days;

minor injury: all other injuries, where the injured person is unfit for his or her normal work for less than three days;

damage only: damage to property, equipment, the environment or production losses. (This guidance only deals with events that have the potential to cause harm to people.)

causes of adverse events:

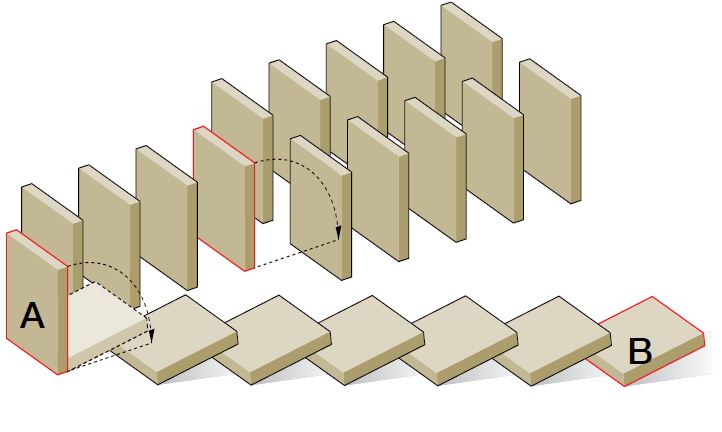

Adverse events have many causes. What may appear to be bad luck (being in the wrong place at the wrong time) can, on analysis, be seen as a chain of failures and errors that lead almost inevitably to the adverse event. (This is often known as the Domino effect.)

These causes can be classified as:

- immediate causes: the agent of injury or ill health (the blade, the substance, the dust etc);

- underlying causes: unsafe acts and unsafe conditions (the guard removed, the ventilation switched off etc);

root causes: the failure from which all other failings grow, often remote in time and space from the adverse event (eg failure to identify training needs and assess competence, low priority given to risk assessment etc).

To prevent adverse events, you need to provide effective risk control measures which address the immediate, underlying and root causes.

Why investigate?

There are hazards in all workplaces; risk control measures are put in place to reduce the risks to an acceptable level to prevent accidents and cases of ill health. The fact that an adverse event has occurred suggests that the existing risk control measures were inadequate. Learning lessons from near misses can prevent costly accidents. (The Clapham Junction rail crash and the Herald of Free Enterprise ferry capsize were both examples of situations where management had failed to recognise, and act on, previous failings in the system.) You need to investigate adverse events for a number of reasons.

Legal reasons for investigating:

- To ensure you are operating your organisation within the law.

- he Management of Health and Safety at Work Regulations 1999, regulation 5, requires employers to plan, organise, control, monitor and review their health nand safety arrangements. Health and safety investigations form an essentialnpart of this process.

- Following the Woolf Report6 on civil action, you are expected to make full disclosure of the circumstances of an accident to the injured parties considering legal action.

Benefits arising from an investigation:

- The prevention of further similar adverse events. If there is a serious accident, the regulatory authorities will take a firm line if you have ignored previous warnings.

- The prevention of business losses due to disruption, stoppage, lost orders and the costs of criminal and civil legal actions.

- An improvement in employee morale and attitude towards health and safety. Employees will be more cooperative in implementing new safety precautions if they were involved in the decision and they can see that problems are dealt with.

- The development of managerial skills which can be readily applied to other areas of the organisation.

Which events should be investigated?

Having been notified of an adverse event and been given basic information on what happened, you must decide whether it should be investigated and if so, in what depth.

It is the potential consequences and the likelihood of the adverse event recurring that should determine the level of investigation, not simply the injury or ill health suffered on this occasion. For example: Is the harm likely to be serious? Is this likely to happen often? Similarly, the causes of a near miss can have great potential for causing injury and ill health. When making your decision, you must also consider the potential for learning lessons. For example if you have had a number of similar

adverse events, it may be worth investigating, even if each single event is not worth investigating in isolation. It is best practice to investigate all adverse events which may affect the public.

Who should carry out the investigation?

For an investigation to be worthwhile, it is essential that the management and the workforce are fully involved. Depending on the level of the investigation (and the size of the business), supervisors, line managers, health and safety professionals, union safety representatives, employee representatives and senior management/directors may all be involved.

As well as being a legal duty, it has been found that where there is full cooperation and consultation with union representatives and employees, the number of accidents is half that of workplaces where there is no such employee involvement.

This joint approach will ensure that a wide range of practical knowledge and experience will be brought to bear and employees and their representatives will feel empowered and supportive of any remedial measures that are necessary. A joint approach also reinforces the message that the investigation is for the benefit of everyone.

In addition to detailed knowledge of the work activities involved, members of the team should be familiar with health and safety good practice, standards and legal requirements. The investigation team must include people who have the necessary investigative skills (eg information gathering, interviewing, evaluating and analysing). Provide the team with sufficient time and resources to enable them to carry out the investigation efficiently.

When should it start?

The urgency of an investigation will depend on the magnitude and immediacy of the risk involved (eg a major accident involving an everyday job will need to be investigated quickly).

In general, adverse events should be investigated and analysed as soon as possible. This is not simply good practice; it is common sense – memory is best and motivation greatest immediately after an adverse event.

What does it involve?

An investigation will involve an analysis of all the information available, physical (the scene of the incident), verbal (the accounts of witnesses) and written (risk assessments, procedures, instructions, job guides etc), to identify what went wrong and determine what steps must be taken to prevent the adverse event from happening again.

It is important to be open, honest and objective throughout the investigation process. Pre-conceived ideas about the process, the equipment or the people involved in an adverse event may blind you to the real causes. Question everything. Be wary of blaming individuals.

What makes a good investigation?

To get rid of weeds you must dig up the root. If you only cut off the foliage, the weed will grow again.

Similarly it is only by carrying out investigations which identify root causes that organisations can learn from their past failures and prevent future failures.

Simply dealing with the immediate causes of an adverse event may provide a shortterm fix. But, in time, the underlying/root causes that were not addressed will allow conditions to develop where further adverse events are likely, possibly with more serious consequences. It is essential that the immediate, underlying causes and root causes are all identified and remedied.

The objective is to establish not only how the adverse event happened, but more importantly, what allowed it to happen.

The root causes of adverse events are almost inevitably management, organisational or planning failures.

Look carefully at your health and safety policy and how it is reflected in the workplace. Do staff understand the health and safety message in general and in particular those parts that relate to their work? Is something missing from the policy? Is it implemented, or is management failing to ensure that health and safety measures remain in place and are effective at all times? If not, your health and

safety policy needs to be changed.

The investigation should be thorough and structured to avoid bias and leaping to conclusions. Don’t assume you know the answer and start finding solutions before you complete the investigation. A good investigation involves a systematic and structured approach.

Information gathering:

- explores all reasonable lines of enquiry;

- is timely;

- is structured, setting out clearly what is known, what is not known and records

- the investigative process.

Analysis:

- is objective and unbiased;

- dentifies the sequence of events and conditions that led up to the adverse event;

- identifies the immediate causes;

- identifies underlying causes, ie actions in the past that have allowed or caused undetected unsafe conditions/practices;

- identifies root causes, (ie organisational and management health and safety arrangements – supervision, monitoring, training, resources allocated to health and safety etc).

Risk control measures:

- identify the risk control measures which were missing, inadequate or unused;

- compare conditions/practices as they were with that required by current legal requirements, codes of practice and guidance;

- identify additional measures needed to address the immediate, underlying and root causes;

- provide meaningful recommendations which can be implemented. But woolly recommendations such as ‘operators must take care not to touch the cuttersduring run-down’ show that the investigation has not delved deep enough in search of the root causes.

Action plan and implementation:

- provide an action plan with SMART objectives (Specific, Measurable, Agreed, Realistic and Timescaled);

- ensure that the action plan deals effectively not only with the immediate and underlying causes but also the root causes;

- include lessons that may be applied to prevent other adverse events, eg assessments of skill and training in competencies may be needed for other areas of the organisation;

- provide feedback to all parties involved to ensure the findings and recommendations are correct, address the issues and are realistic;

- should be fed back into a review of the risk assessment. The Approved Code of Practice attached to the Management of Health and Safety at Work Regulations 1999 regulation 3 (paragraph 26), states that adverse events should be a trigger for reviewing risk assessments);

- communicate the results of the investigation and the action plan to everyone who needs to know;

- include arrangements to ensure the action plan is implemented and progressmonitored.

A step by step guide to health and safety investigations:

RIDDOR:

For those accidents and dangerous occurrences that are reportable under the provisions of RIDDOR (the Reporting of Injuries, Diseases and Dangerous Occurrences Regulations 1995), this information must be notified to the enforcing authority.

- keeping a copy of the form;

- recording the incident in the accident book;

- recording the incident electronically.

The investigation:

The four steps include a series of numbered questions. These set out in detail the information that should be entered onto the adverse event investigation form. The question numbers correspond to those on the form.

Step one Gathering the information

Find out what happened and what conditions and actions influenced the adverse event. Begin straight away, or as soon as practicable.

It is important to capture information as soon as possible. This stops it being corrupted, eg items moved, guards replaced etc. If necessary, work must stop and unauthorised access be prevented.

Talk to everyone who was close by when the adverse event happened, especially those who saw what happened or know anything about the conditions that led to it.

The amount of time and effort spent on information gathering should be proportionate to the level of investigation. Collect all available and relevant information. That includes opinions, experiences, observations, sketches, measurements, photographs, check sheets, permits-to-work and details of the environmental conditions at the time etc. This information can be recorded initially in note form, with a formal report being completed later. These notes should be kept at least until the investigation is complete.

Where, when and who?

1 Where and when did the adverse event happen?

2 Who was injured/suffered ill health or was otherwise involved with the adverse event?

Gathering detailed information: How and what?

Discovering what happened can involve quite a bit of detective work. Be precise and establish the facts as best you can. There may be a lack of information and many uncertainties, but you must keep an open mind and consider everything that might have contributed to the adverse event. Hard work now will pay off later in the investigation.

Many important things may emerge at this stage of the process, but not all of them will be directly related to the adverse event. Some of the information gathered may appear to have no direct bearing on the event under investigation. However, this information may provide you with a greater insight into the hazards and risks in your workplace. This may enable you to make your workplace safer in ways you may not have previously considered.

3. How did the adverse event happen? Note any equipment involved.

Describe the chain of events leading up to, and immediately after, the adverse event. Very often, a number of chance occurrences and coincidences combine to create the circumstances in which an adverse event can happen. All these factors should be recorded here in chronological order, if possible. Work out the chain of events by talking to the injured person, eye witnesses, line managers, health and safety representatives and fellow workers to find out what happened and who did what. In particular, note the position of those injured, both immediately before and after the adverse event. Be objective and, as far as possible, avoid apportioning guilt, assigning responsibility or making snap judgements on the probable causes.

4 What activities were being carried out at the time?

The work that was being done just before the adverse event happened can often cast light on the conditions and circumstances that caused something to go wrong. Provide a good description, including all the relevant details, eg the surroundings, the equipment/materials being used, the number of employees engaged in the various activities, the way they were positioned and any details about the way they were behaving etc.

5 Was there anything unusual or different about the working conditions?

Adverse events often happen when something is different. When faced with a new situation, employees may find it difficult to adapt, particularly if the sources of danger are unknown to them, or if they have not been adequately prepared to deal with the new situation. If working conditions or processes were significantly different to normal, why was this?

Describe what was new or different in the situation. Was there a safe working method in place for this situation, were operatives aware of it, and was it being followed? If not, why not? Learning how people deal with unfamiliar situations will enable similar situations to be better handled in the future.

6 Were there adequate safe working procedures and were they followed?

Adverse events often happen when there are no safe working procedures or where procedures are inadequate or are not followed. Comments such as ‘…we’ve been doing it that way for years and nothing has ever gone wrong before…’ or ‘…he has been working on that machine for years and knows what to do…’ often lead to the injured person getting the blame, irrespective of what part procedures, training and supervision – or the lack of them – had to play in the adverse event. What was it about normal practice that proved inadequate? Was a safe working method in place and being followed? If not, why not? Was there adequate supervision and were the supervisors themselves sufficiently trained and experienced? Again, it is important to pose these questions without attempting to apportion blame, assign responsibility or stipulate cause.

7 What injuries or ill health effects, if any, were caused?

It is important to note which parts of the body have been injured and the nature of the injury - ie bruising, crushing, a burn, a cut, a broken bone etc. Be as precise as you are able. If the site of the injury is the right upper arm, midway between the elbow and the shoulder joint, say so. Precise descriptions will enable you to spot trends and take prompt remedial action. For example it could be that what appears to be a safe piece of equipment, due to the standard of its guarding, is actually

causing a number of inadvertent cut injuries due to the sharp edges on the guards themselves.

8 If there was an injury, how did it occur and what caused it?

Where an accident is relatively straightforward, it may seem artificial to differentiate between the accident itself (question 3) and the mode of injury, but when the accident is more complicated the differences between the two aspects become clearer and therefore precise descriptions are vital.

The mode of injury concerns two different aspects:

- the harmful object (known as the ‘agent’) that inflicted the injury; and

- the way in which the injury was actually sustained.

9 Was the risk known? If so, why wasn’t it controlled? If not, why not?

You need to find out whether the source of the danger and its potential consequences were known, and whether this information was communicated to those who needed to know. You should note what is said and who said it, so that potential gaps in the communication flow may be identified and remedied. The aim is to find out why the sources of danger may have been ignored, not fully

appreciated or not understood. Remember you are investigating the processes and systems, not the person.

10 Was the safety equipment sufficient?

You should satisfy yourself that any safety equipment and safety procedures are both sufficient and current for all conditions in which work takes place, including the provision and use of any extra equipment needed for employees’ safety. For example:

- extra technical safety equipment at machines;

- power supply isolation equipment and procedures;

- personal protective equipment (PPE);

- building safety systems, eg an extract ventilation system.

Step two Analysing the information:

An analysis involves examining all the facts, determining what happened and why. All the detailed information gathered should be assembled and examined to identify what information is relevant and what information is missing. The information gathering and analysis are actually carried out side by side. As the analysis progresses, further lines of enquiry requiring additional information will develop.

To be thorough and free from bias, the analysis must be carried out in a systematic way, so all the possible causes and consequences of the adverse event are fully considered. A number of formal methods have been developed to aid this approach.

One useful method for organising your information, identifying gaps and beginning the analysis is Events and Causal Factor Analysis (ECFA), which is beyond the scope of this guidance.

The analysis should be conducted with employee or trade union health and safety representatives and other experts or specialists, as appropriate. This team approach can often be highly productive in enabling all the relevant causal factors to emerge.

Analysis:

There are many methods of analysing the information gathered in an investigation to find the immediate, underlying and root causes and it is for you to choose whichever method suits you best.

What happened and why?

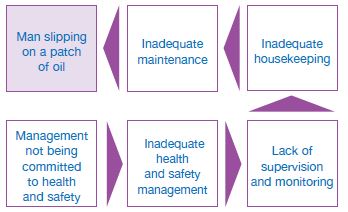

The first step in understanding what happened and why is to organise the information you have gathered. This guidance uses the simple technique of asking ‘Why’ over and over, until the answer is no longer meaningful (see Figure 1). The starting point is the ‘event’, eg John has broken his leg. On the line below, set out the reasons why this happened. This first line should identify:

- the vulnerable person, eg John on a ladder;

- the hazard, eg falling due to gravity;

- the circumstances that brought them together, eg John fell off the ladder.

For each of the reasons identified ask ‘Why?’ and set down the answers. Continue down the page asking ‘Why’ until the answers are no longer meaningful.

Do not be concerned at the number of times you ask the question, ‘Why?’ because by doing so you will arrive at the real causes of the adverse event. Some lines of enquiry will quickly end, eg ‘Why was the hazard of falling present?’

Answer: ‘Gravity’.

Having collected the relevant information and determined what happened and why, you can now determine the causes of the adverse event systematically.

Checklist/question analysis of the causes:

Using the adverse event analysis work sheets and checklist (in the Adverse Eventand Investigation Form), work through the questions about the possible immediate causes of the adverse event (the place, the plant, the people and the process) and identify which are relevant.

Record all the immediate causes identified and the necessary risk control measures.

For each immediate cause, the analysis suggests underlying causes which may have allowed the immediate causes to exist.

Consider the underlying/root cause questions suggested by the immediate causes. Record those that are relevant and note the measures needed to remedy them. The final step of your analysis is to consider the environment in which the organisation and planning of health and safety was carried out.

Job factors:

- how much attention is needed for the task (both too little and too much can lead to higher error rates)?

- divided attention or distractions are present;

- inadequate procedures;

- time available.

Human factors:

- physical ability (size and strength);

- competence (knowledge, skill and experience);

- fatigue, stress, morale, alcohol or drugs.

Organisational factors:

- work pressure, long hours;

- availability of sufficient resources;

- quality of supervision;

- management beliefs in health and safety (the safety culture).

Plant and equipment factors:

- how clear and simple to read and understand are the controls?

- is the equipment designed to detect or prevent errors? (For example differentsized connectors are used for oxygen and acetylene bottles to prevent errors in connecting the hoses);

- is the workplace layout user-friendly?

Step three Identifying suitable risk control measures:

The methodical approach adopted in the analysis stage will enable failings and possible solutions to be identified. These solutions need to be systematically evaluated and only the optimum solution(s) should be considered for implementation. If several risk control measures are identified, they should be carefully prioritised as a risk control action plan, which sets out what needs to be done, when and by whom. Assign responsibility for this to ensure the timetable for implementation is monitored.

What risk control measures are needed/recommended?

Your analysis of the adverse event will have identified a number of risk control measures that either failed or that could have interrupted the chain of events leading to the adverse event, if they had been in place. You should now draw up a list of all the alternative measures to prevent this, or similar, adverse events.

Some of these measures will be more difficult to implement than others, but this must not influence their listing as possible risk control measures. The time to consider these limitations is later when choosing and prioritising which measures to implement.

Evaluate each of the possible risk control measures on the basis of their ability to prevent recurrences and whether or not they can be successfully implemented. In deciding which risk control measures to recommend and their priority, you should choose measures in the following order, where possible:

measures which eliminate the risk, eg use ‘inherently safe’ products, such as a water-based product rather than a hydrocarbon-based solvent;

- measures which combat the risk at source, eg provision of guarding;

- measures which minimise the risk by relying on human behaviour, eg safe working procedures, the use of personal protective equipment.

Do similar risks exist elsewhere? If so, what and where?

Having concluded your investigation of the adverse event, consider the wider implications: could the same thing happen elsewhere in the organisation, on this site or at another location? What steps can be taken to avoid this? Adverse events might not have occurred at other locations yet, but make an

evaluation as to whether the risks are the same and the same or similar risk control measures are appropriate.

Have similar adverse events happened before? Give details.

If there have been similar adverse events in the past why have they been allowed to happen again? The fact that such adverse events are still occurring should be a spur to ensure that action is taken quickly. You will be particularly open to criticism if you as an organisation ignore a series of similar accidents.

Remember that there is value in investigating near-misses and undesired circumstances: it is often only a matter of luck that such incidents do not result in serious injuries or loss of life.

Step four The action plan and its implementation:

The risk control action plan:

At this stage in the investigation, senior management, who have the authority to make decisions and act on the recommendations of the investigation team, should be involved.

An action plan for the implementation of additional risk control measures is the desired outcome of a thorough investigation. The action plan should have SMART objectives, ie Specific, Measurable, Agreed, and Realistic, with Timescales.

Deciding where to intervene requires a good knowledge of the organisation and the way it carries out its work. For the risk control measures proposed to be SMART, management, safety professionals, employees and their representatives should all contribute to a constructive discussion on what should be in the action plan.

Not every risk control measure will be implemented, but the ones accorded the highest priority should be implemented immediately. In deciding your priorities you should be guided by the magnitude of the risk (‘risk’ is the likelihood and severity of harm). Ask yourself ‘What is essential to securing the health and safety of the workforce today?’ What cannot be left until another day? How high is the risk to employees if this risk control measure is not implemented immediately? If the risk is high, you should act immediately.

You will, no doubt, be subject to financial constraints, but failing to put in place measures to control serious and imminent risks is totally unacceptable. You must either reduce the risks to an acceptable level, or stop the work.

It is crucial that a specific person, preferably a director, partner or senior manager, is made responsible for ensuring that the action plan as a whole is put into effect. This person doesn’t necessarily have to do the work him or herself but he or she should monitor the progress of the risk control action plan.

Progress on the action plan should be regularly reviewed. Any significant departures from the plan should be explained and risk control measure rescheduled, if appropriate. Employees and their representatives should be kept fully informed of the contents of the risk control action plan and progress with its implementation

Which risk assessments and safe working procedures need to be reviewed and updated?

All relevant risk assessments and safe working procedures should be reviewed after an adverse event. The findings of your investigation should indicate areas of your risk assessments that need improving. It is important that you take a step back and ask what the findings of the investigation tell you about your risk assessments in general. Are they really suitable and sufficient?

What did the adverse event cost?

In addition to the prompt notification of RIDDOR reportable events to the regulatory authorities you should ensure that you keep your own records of adverse events, their causes and the remedial measures taken. This will enable you to monitor yourbhealth and safety performance and detect trends, the common causes of adverseb events and so improve your overall understanding and management of risk.

It is also useful to estimate the cost of adverse events to fully appreciate the true cost of accidents and ill health to your business. The step by step approach that is set out in this guide is only one of a number of possible approaches. It is for you to decide which approach suits your businessbest.

Click the below link to download Investigation forms and PPT

Accident and Incident -Power point presentation

Initial assessment and Investigation form