Laser safety:

Introduction:

The Laser Safety Manual describe laser safety program and provides guidance for the safe use of lasers and laser systems. This has adopted the elements of this program to assist researchers in conducting work with lasers as safely as possible while also meeting reasonable and legally defensible standards of precaution in the use of lasers. The program is intended to minimise record keeping, follow accepted good practices, and provide useful resource materials for laser users. Comments on the program and manual content are always welcome and may be addressed to either the Laser Safety Officer or the Laser Safety Committee.

The information contained in this manual is based on the American National Standard for the Safe Use of Lasers, ANSI Z136.1-2000. Although the Z136.1 standard is frequently cited in this manual, for more thorough guidance the complete standard should be reviewed.

Manual Organisation:

Manual Organisation:

This Manual is divided into three sections

(1) Laser Safety Program,

(2) Classification and Control,

(3) Non-Beam Hazards and

- Section One, Laser Safety Program, describes the program roles and responsibilities of the individual laser users, principal investigators, Laser Safety Committee, and campus Administration.

- Section Two, Classification and Control, addresses laser safety based on the classification scheme and required control measures of the Z136.1 standard.

- Section Three, Non-Beam Hazards, identifies the typical non-beam or ancillary hazards of laser systems.

Section 1 : LASER SAFETY PROGRAM

Individual Laser Users:

Individual laser users must be aware of and responsible for:

- Attending laser safety training sessions as determined by the hazard classification of the laser they intend to operate.

- Reviewing, understanding and complying with the laser safety procedures prior to operating their laser system.

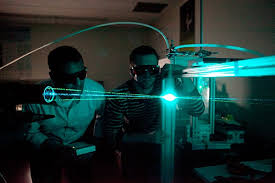

- Wearing required protective equipment, such as approved eye wear and protective clothing.

- Maintaining engineering controls (e.g., interlocks not defeated) on the laser system as designed, specified and approved by the laser manufacturer, or the principal investigator, in consultation with the LSO. Assuring that safety features which are not functioning properly are reported to the principal investigator.

- Promptly reporting the details of any accident involving a laser to the principal investigator.

Principal Investigators:

Principal investigators are responsible for assuring that the use of lasers under their supervision complies with Laser Safety Committee policy, as described in this manual.

Specific responsibilities include:

- Notifying the Laser Safety Officer whenever the principal investigator acquires, fabricates, transfers a laser to a different laboratory, or changes the hazard classification of a laser system. Notification can be accomplished by submitting a completed laser inventory form to EH&S.

- Developing written laser safety procedures for Class 4 lasers and ensuring that laser operations are carried out in accordance with those procedures. Laser safety procedures must be posted near the laser system or made readily available for review.

- Ensuring that laser operators, prior to actually using lasers, are properly instructed and trained in laser safety and are familiar with the laser safety procedure for their laser system. Training must be documented for all employees. Visitors to areas or laboratories in which lasers are used must also be informed of the hazards and control measures associated with these systems.

- Ensuring that laser maintenance and repair work are performed by qualified, trained individuals and conducted in a safe manner.

- Promptly notifying the Laser Safety Officer and discontinuing operation of a laser when an accident related to laser use has occurred.

Laser Safety Committee (LSC):

The Laser Safety Committee (LSC) consists of faculty, staff and student members who function as a peer review committee and are selected from departments where lasers are used. The LSC is appointed by the Vice Chancellor, Administrative Services, and is responsible for establishing and enforcing campus policies relating to laser safety. The Laser Safety Committee serves as an adviser to the campus Administration on matters relevant to laser safety and is the ultimate reviewing and authorising agent for the use of lasers on campus.

Laser Safety Officer (LSO)

The Laser Safety Officer is a member of the Laser Safety Committee, carries out the directives of the Committee and advises on the overall status of the laser safety program. Major responsibilities and duties of the Laser Safety Officer are:

Providing knowledgeable consultation and evaluation of laser hazards, reviewing and approving the written laser safety plan for a particular laser system.

- Ensuring that the campus use of lasers is in conformance with Laser Safety Committee policy.

- Maintaining records related to the campus laser safety program. Typical records include the laser inventory, accident investigations, hazard analysis and laser safety training.

- Inspecting and auditing laser systems and operations.

- Classifying or verifying the classification of laser systems.

- Suspending, restricting or terminating the operation of a laser system if the LSO

- considers the laser's hazard controls inadequate.

- Investigating any real or suspected accident resulting from a laser operation, and initiating appropriate corrective action.

Environmental Health and Safety (EH&S)

Environmental Health and Safety is responsible for: surveillance of laser operations through the staffing of a campus Laser Safety Officer (LSO); providing consultation and laser safety services in conformance with the policies set forth in this manual, governmental regulations, and national laser safety standards. EH&S is authorised to inspect all areas of campus operations and activities.

Medical Surveillance

Medical surveillance needs of personnel working in a laser environment are the same as for other potential health hazards. Medical surveillance examinations may include assessment of physical fitness to safely perform assigned duties, biological monitoring of exposure to a specific agent, and early detection of biologic damage or effect.

Medical surveillance is strongly recommended for laser operators of Class 3b, and Class 4 laser systems. Laser operators should have, at a minimum, a baseline examination of the following, as specified in ANSI Z1361:

- Ocular history

- Visual acuity

- Macular function

- Color Vision

- Ocular Fundus with an Ophthalmologist

- Skin

CLASSIFICATION AND CONTROL

Hazard Classification:

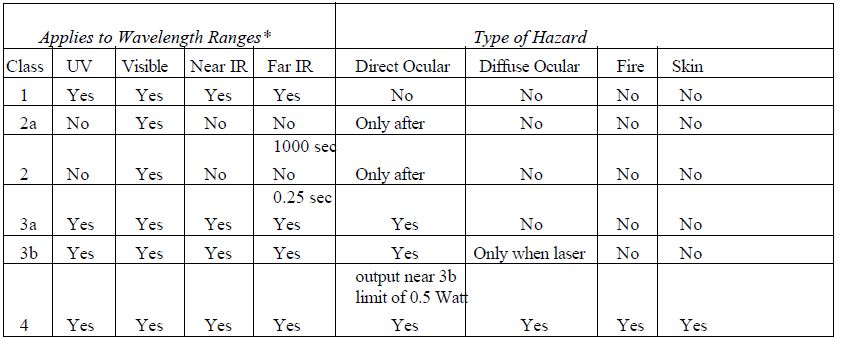

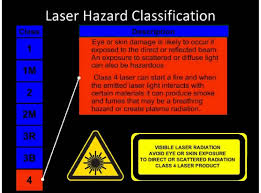

The four laser hazard classes, along with their subdivisions, are:

Class 1

Class 1 lasers are considered safe based on current medical knowledge. This class includes lasers which cannot emit levels of optical radiation in excess of the exposure limit for the eye (i.e. Maximum Permissible Exposure) under any exposure condition inherent in the design and intended use of the laser. A Class 1 laser system may contain a more hazardous laser embedded in the enclosure, but no harmful levels of the laser radiation can escape the system enclosure. For Class 1 lasers containing an embedded higher class of laser, the enclosure must be interlocked.

Class 2

All Class 2 lasers operate in the visible wavelength region (400-700 nm), are sub-divided into

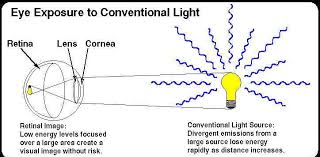

Classes 2a and 2, and are considered low-power lasers operating at less than 1 milliWatt. Class 2a lasers are not intended for prolonged viewing of the beam, but under normal operating conditions would not be hazardous if viewed directly (i.e. intrabeam viewing) for periods not exceeding 1,000 seconds. Class 2 lasers are not considered hazardous for momentary viewing of the direct beam for up to 0.25 seconds (i.e., aversion response time). The aversion response, blinking of eye and turning away, will afford ample protection from the beam of all Class 2 lasers. However, a Class 2 laser beam could be hazardous if one were to intentionally overcome the aversion response and stare directly into the beam for longer than 0.25 seconds. As a comparison, conventional bright light sources are also considered hazardous if one were to overcome the natural aversion response and directly stare into the light for an extended period.

Class 3

A Class 3 laser system can emit any wavelength, but cannot produce a hazardous diffuse reflection unless viewed for extended periods at close range or with collecting optics. Class 3 is subdivided into Class 3a and Class 3b. Class 3a lasers would normally not present a hazard if viewed directly for momentary periods with the unaided eye (i.e., without collecting optics) and operate at 1 to 5 milliWatts for those emitting a continuous wave beam. Class 3b lasers operate at 5 to 500 MW for continuous wave. The beam from all Class 3 lasers are not considered a fire, skin, or a diffuse reflection hazard.

Class 4

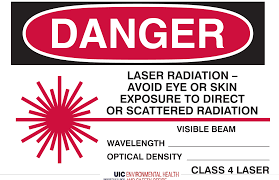

Class 4 laser systems can emit any wavelength, exceed 500 milliWatts, and are considered a fire, skin, and a diffuse reflection hazard. The most stringent control measures have been established for these lasers.

Laser Hazard Classes:

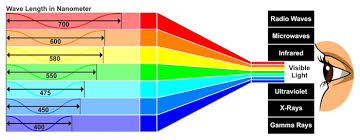

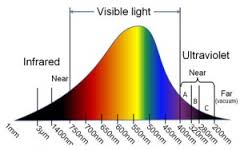

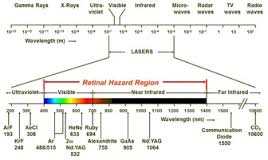

Various ranges, in nano meters, are:

- Ultraviolet (100-400)

- Visible (400-700)

- Near Infrared (700-1400)

- Far Infrared (1400-106).

Maximum Permissible Exposure:

Maximum Permissible Exposure (MPE) levels have been established by ANSI Z136.1 for various laser wavelengths and exposure durations. The MPE is the level of laser radiation to which a person may be exposed without hazardous effect or adverse biological changes in the eye or skin. In most cases it is unnecessary to make use of the MPE directly, if the laser hazard class is known and appropriate controls for that hazard class are implemented. Since the determination of the MPE for various wavelengths and exposure situations can be quite complicated, the complete ANSI Z136.1 standard or the Laser Safety Officer should be consulted for further information.

It is good practice to maintain exposure levels as far below the MPE values as possible. One

reason is that exposure to levels at the MPE values may be uncomfortable to view or feel upon the skin. MPEs for the eye and skin, along with correction factors for certain wavelengths, are listed on Tables 5 (a,b), 6 and 7 of this manual.

0.25 second: The human aversion time (i.e., blinking, turning away) for a bright light stimulus, which only applies to visible wavelengths (400-700 nm). The aversion response becomes the first line of defence for unexpected exposure to Class 2 lasers.

10 seconds: The time period chosen by the ANSI Z136.1 committees that represents the “worst

case” time period for ocular exposure to an infrared (principally near infrared) laser beam. Eye movements provide a natural exposure limitation, eliminating the need for calculations

greater than 10 seconds, except for unusual viewing conditions.

600 seconds: The time period chosen by the ANSI Z136.1 committees that represents the typical "worst case" time period for viewing visible diffuse reflections during tasks such as

alignment.

30,000 seconds: The time period that represents a full one-day (8 hour) occupational exposure. This results from computing the number of seconds in 8 hours (28,800 seconds) and rounding it off to 30,000.

Nominal Hazard Zone (NHZ):

The nominal hazard zone (NHZ) is a term used in ANSI Z136.1 to describe the space within which the level of direct, scattered or reflected laser light emitted during laser operation exceeds the MPE. Outside of the nominal hazard zone, the level of laser radiation is less than the applicable MPE.

The NHZ allows one to eliminate more restrictive Class 4 laser control measures if an area falls outside the NHZ. For instance, if the NHZ does not extend to the doorway in a laser laboratory, the door need not be safety interlocked or have a safety latch. This would eliminate the inconvenience of disrupting laser operation when frequent passage through the doorway is required. The NHZ boundary would, however, need to be visibly identified with tape or other suitable means. At the entryway to the NHZ, a warning sign is required which indicates the laser hazard, with special precautions and instructions written on the sign.

Laser Hazard Control Measures:

Control measures are established in the Z136.1 standard as a means of reducing the possibility

of skin and eye exposure to laser radiation, during normal operation and maintenance,above their respective MPE values. Hazard control measures can be grouped into three general categories:

- Engineering (e.g., enclosures, interlocks, beam stops)

- Administrative (e.g., policies, laser safety procedures, training)

- Personnel Protective Equipment (e.g., eye wear, clothing)

Maximum emphasis should be placed on engineering control measures. However, if engineering controls are impractical or inadequate, warning devices, personnel protective equipment or administrative controls must be used. During the development of written laser safety procedures, one must consider the limitations of control measures (e.g., failure modes of enclosure, eye protection damage thresholds, inability of some personnel to understand written warnings). For all uses of lasers and laser systems, it is recommended that the minimum laser beam energy or power be used for the application and the beam location maintained at a height other than eye level for one seated or standing. If it is not feasible to locate the beam at a height other than eye level, the beam should be enclosed.

Engineering Controls:

Protective Housing:

Required on all classes of lasers. In certain instances, operation of a laser or laser system without a protective housing may be necessary. In these instances, the Laser Safety Officer will conduct a hazard analysis and assure that alternative controls are used. Alternate controls may include, but are not limited to:

- access restrictions

- eye protection

- area controls

- barriers, shrouds, beams stops, or other suitable measures.

- additional training and administrative controls.

Interlocks on Protective Housing

Class 3b and Class 4 lasers require an interlocked protective housing, which is activated when

the protective housing is opened during operation and maintenance. The interlock is designed to prevent access to the beam above the applicable MPE. The interlock can be, for instance, mechanically or electrically interfaced with a shutter.

Service Access Panel

Panels of the protective housing which are intended to be removed only by service personnel, thereby permitting access to a Class 3b or Class 4 beam, must either be interlocked or require

a special tool for removal. A label must be affixed to the panel which reads: “Caution-Laser Radiation Inside. Avoid Exposure.”

Key Control

A master switch operated by a key, or by coded access (e.g., computer code). The appropriate

supervisor is vested with the authority to enable the master switch. The master switch is disabled when the laser is not intended to be used.

Viewing Portals

Viewing portals and display screens shall incorporate a suitable method (e.g., interlocks, filters, attenuates) to assure that personnel are not exposed to laser radiation greater than the applicable MPE during conditions of operation and maintenance.

Collecting Optics

Suitable methods shall be used (e.g., interlocks, filters, attenuates) to ensure that personnel

using collecting optics (e.g., lenses, telescopes, microscopes, endoscopes, etc.) are not exposed

to laser radiation levels greater than the applicable MPE.

Remote Interlock Connectors

A remote interlock connector allows connection to an emergency master disconnect interlock,

or to a room, entryway, floor or area interlock. Safety latches or interlocks are used to deactivate the laser in the event of an unexpected entry into laser controlled areas. The design of interlocks must allow both rapid egress and admittance by laser personnel in emergency situations. The person in charge of the laser controlled area is permitted to momentarily override the room access interlocks when continuous laser operation is necessary, but specification for the momentary override must have the approval of the Laser Safety Officer. Interlocks will not allow automatic re-energising of the power supply, but must be designed so that the power supply or shutter must be reset manually. A control-disconnect switch ("panic button") shall be available for deactivating the laser.

Activation Warning System

Activation warning systems consist of audible sounds (e.g., chimes, bells), warning lights, or a

verbal “countdown” which notifies personnel that the laser is being activated.

Emission Delay

The laser activation warning system is activated a sufficient time prior to actual laser emission, allowing one to initiate action to control exposure to the beam.

Protective Windows

Protective windows include absorbing filters, screens, and barriers that cover facility windows

located in the nominal hazard zone of Class 3b and Class 4 lasers. The filters and barriers are

intended to prevent transmission through the window of laser radiation greater than the applicable MPE.

Administrative Controls:

Laser Safety Procedures

A written laser safety procedure is required for Class 4 laser systems and is recommended for Class 3b systems. The procedure addresses both beam and non-beam hazards and is usually in the form of a checklist or a list of instructions. Laser operators must be thoroughly familiar with the laser safety procedure of their system prior to laser operation. A copy of the procedure must be either posted near the laser or made readily available for review.

Training

Training

The type of laser safety training provided is commensurate with the laser hazard classification and duties of the individual (e.g., laser operator, visitors, other lab personnel). Training will be offered by EH&S and is mandatory for those who operate a Class 3b or Class 4 laser. The following topics are included in the laser safety training provided by EH&S:

- Fundamentals of laser operation (physical principles, components of a laser)

- Biological effects of laser radiation on the eye and skin

- Spectacular and diffuse reflections

- Non-beam hazards

- Laser hazard classification and control measures

- Overview of ANSI Z136.1 standard

- Elements of UCSB’s laser safety program

Additionally, principal investigators must provide supplemental training specific to their laser system for those under their supervision who operate Class 3 or Class 4 lasers. The following topics should be included in the supplemental training provided by principal investigators:

- Laser safety and alignment procedures

- Description of control measures specific to the laser (e.g., eye wear, warning signs, interlocks, access restrictions)

- Non-beam hazards associated with the laser system (e.g., fire, electrical, chemical)

- Emergency procedures and telephone numbers of people to contact in the event of an emergency.

Control of Spectators:

Spectators or visitors must not be permitted into a Class 4 laser controlled area unless:

- Approval from the laser supervisor has been obtained.

- The degree of hazard and avoidance procedures have been explained.

- Appropriate protective measures are implemented.

Service Personnel Training

Service personnel requiring access to Class 3b or Class 4 lasers or laser systems enclosed

within a protective housing or enclosure must comply with the control measures of the embedded laser. The principal investigator must assure that service personnel are properly qualified and aware of beam and non-beam hazards associated with the laser system being serviced.

Indoor Laser Controlled Area

An indoor laser controlled area is an area or room which requires initiation of appropriate engineering and procedural controls and determination of the nominal hazard zone when laser radiation exceeds the MPE. In some cases the nominal hazard zone (envelope around the laser beam where the MPE is exceeded) may be the entire room or area.

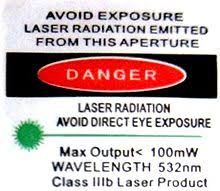

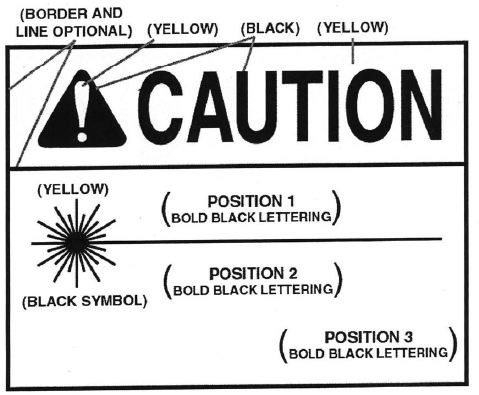

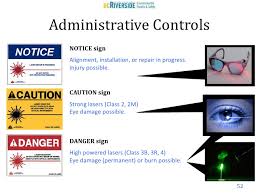

Warning Signs and Labels

Lasers shall have warning labels with the appropriate cautionary or danger statement affixed to a conspicuous place on the laser housing, usually near the aperture of the laser beam. Contact the Laser Safety Officer, EH&S, for door or entry-way warning signs. Laser warning signs must meet the standards of ANSI Z136.1. All signs and labels must be conspicuously displayed in locations which serve to warn personnel. Normally, warning signs are posted on doors, or at entryways into laser controlled areas.

A “Notice”sign is posted whenever a temporary laser controlled area is established during servicing and repair of a laser. When a temporary laser controlled area is created, the area outside the temporary area remains Class 1, with the "Notice" sign posted at the entryway. The area within a temporary laser controlled area is either Class 3b or Class 4 and theappropriate danger warning sign is posted within this area.

Personal Protective Equipment:

Eye Protection

Lasers can produce serious injury to the eyes if adequate protection is not worn. A laser eye

protection device can be defined as a filter which is designed to reduce light transmission of a

specific wavelength, or range of wavelengths, to a safe level while maintaining adequate light

transmission at all other wavelengths. Eye-protection devices which are specifically designed for protection against the emitted wavelength of the laser should be used when engineering and procedural controls are inadequate.

All laser protective eye wear shall be clearly labelled with the optical density values and wavelengths at which the particular eye wear affords protection. The optical density of laser

protective eye wear at a specific wavelength is given as:

OD= Log10 H0/MPE

where H0 is the anticipated worst case exposure (in mW/cm2 or J/cm2) to the eye. The MPE is

expressed in the same units as the those of H0. Adequate optical density at the laser wavelength of interest must be weighed with the need for adequate transmission of visible light. Periodic inspections must be made of protective eye wear to ensure that pitting, cracking or bleaching will not endanger the wearer. The frame of the protective eye wear should also be inspected for mechanical integrity and light leaks.

Skin Protection:

Skin protection may be required if one is likely to be chronically exposed to scattered ultraviolet light, such as during excimer laser applications, or acutely exposed to levels greater than the MPE for the skin. If exposure of the body to a concentrated, high-power laser beam is likely, such as greater than 100 watts in a 1 cm diameter beam, then one must consider skin as well as eye protection. One should always strive, if the laser application permits, to enclose as much of the beam as possible, or to use protective barriers. Skin protection is required when personnel are exposed to laser radiation greater than the MPE for the skin.

Where personnel are subject to chronic skin exposure from UV radiation, even at levels less than the MPE for the skin (e.g., certain excimer laser applications), skin covers and/or " sun screen" creams are recommended.

Leather gloves,leather aprons and jackets are generally considered the most desirable in protection against UV exposure. Woven fabrics vary greatly in their attenuation properties. Loosely woven fabrics, through which one can readily see light when held up to a light source, have a UV-B diffuse transmission ranging from 5% to 30%. Rayon and rayon blends transmit somewhat less (10 to 15%), and heavy wool and flannel materials may transmit 1% or less. Poplin is reported to have very low transmittance. Nylon is very ineffective with a transmission of 20% to 40%. This is important to note since many lab coats are nylon based. Attenuation of laser light can also be greatly enhanced by the use of layered clothing.

Factors Common to Laser Accidents:

When evaluating a particular laser system and developing a laser safety procedure, it is useful to review some of the common factors involved in previous laser accidents. The following circumstances are most often reported by laser manufacturers to the Food and Drug Administration as the cause of personnel injuries from both the laser beam and other non beam hazards.

Unanticipated eye exposure during alignment

- Misaligned optics

- Available eye protection not used

- Equipment malfunction

- Improper methods of handling high voltage

- Intentional exposure of unprotected personnel

- Operators unfamiliar with laser equipment

- Lack of protection for ancillary (non-beam) hazards

- Improper restoration of equipment following service

NON-BEAM HAZARDS:

Non-beam hazards of laser systems may include electrical, fire, explosion, other optical radiation hazards, compressed gases, cryogenic, toxic and carcinogenic materials, noise, ionising radiation and toxic air contaminants from beam interaction with a target material. These hazards must be evaluated separately by each principal investigator for their specific laser system and appropriate control measures for these hazards incorporated in the laser safety procedure. Additional

Electrical:

The most lethal hazard associated with lasers is the electrical hazard. Electrocution, burns and

severe shock have occurred to a number of individuals trouble-shooting or servicing laser equipment. To prevent electrical injuries, all personnel should be adequately trained and the

“buddy system” used whenever working around high voltage laser power supplies. Training in Cardiopulmonary Resuscitation (CPR) is recommended for all laser service personnel, research personnel, and their assistants.

The following potential problems have frequently been identified during laser facility audits:

Uncovered or improperly insulated electrical terminals

- Hidden “power-up” warning lights

- Lack of personnel trained in CPR, or lack of refresher training

- “Buddy system” not being practices during maintenance and service

- Non earth-grounded or improperly grounded laser equipment

- Non adherence to the OSHA lock-out standard (29 CFR 1910.147)

- Excessive wires and cables on floor that create a fall or slip hazard

Capacitor

Explosion

High-pressure arc lamps and filament lamps in laser equipment shall be enclosed in housings

which can withstand the maximum explosive pressures resulting from lamp disintegration. The laser target and elements of the optical train, which may shatter during laser operation, should also be enclosed or equivalently protected to prevent injury to operators and observers.

Fire

Enclosures and beam stops of Class 4 lasers can result in potential fire hazards if they are likely to be exposed to irradiates exceeding 10 W/cm2 or to beam powers greater than 0.5 watts. In these instances, the use of flame-resistant materials should be encouraged. Operators should also be aware of unprotected wire insulation and plastic tubing catching fire from intense reflected or scattered beams of Class 4 lasers, especially those operating at invisible wavelengths.

Optical Radiation (other than laser beam)

Ultraviolet radiation emitted from laser discharge tubes and pumping lamps (i.e., not part of the primary laser beam) must be suitably shielded so that personnel exposures do not exceed the threshold limit values (TLV) specified by the American Conference of Governmental Industrial Hygienists. Optical flash tubes may emit hazardous levels of ultraviolet radiation if quartz tubing is used. The ultraviolet radiation can be readily attenuated by certain plastics and heat-resistant glasses.

Plasma emissions created during a laser-welding process may have sufficient ultraviolet and/or blue light content (0.2 to 0.55 μm) to be of concern to operators; especially those who are not adequately protected and are viewing the laser-welding process on a long-term basis.

Other Considerations

Examples of other concerns include hazards associated with cryogenic gases, toxic and carcinogenic material and noise.

When target irradiates exceed a certain threshold, approximately 107 W/cm2, certain target materials may liberate toxic and noxious airborne contaminants.

These Laser Generated Airborne Contaminants (LGAC) depend greatly on the laser beam irradiance and the chemical composition of the target. Adequate local exhaust ventilation shall be installed to reduce potentially hazardous fumes and vapors produced by laser target interactions to levels below the appropriate threshold limit values specified by the American Conference of Governmental Industrial Hygienists.

A complete listing of all possible non-beam hazards and control measures associated with laser systems is beyond the scope of this manual. Users of lasers systems are encouraged to contact EH&S for an evaluation of their laser system to determine the required control measures for these hazards.

Laser Fundamentals and Bio effects:

Characteristics of Laser Light

A laser is a device which produces an intense, coherent, directional beam of light by stimulating electronic or molecular transitions from excited energy states to lower energy levels. “Laser” is an acronym for Light Amplification by Stimulated Emission of Radiation. A laser system is an assembly of electrical, mechanical, and optical components which includes the laser beam. Laser light is uniquely different than more common light sources due to four important properties:monochromatic, coherence, directional and radiance.

Monochromatic

The color of light is dependent upon the wavelength. Violet has the shortest wavelength, red has the longest and white light is the combination of all visible colors and therefore wavelengths. Laser light consists of only a single color of light, operating within a very narrow band of wavelength.

Coherence

The coherence of laser light actually contributes to most aspects of the other three characteristics and is based on the wave properties of light. Light waves generated by an ordinary light source such as a fluorescent bulb are incoherent, consisting of a mixture of different wavelengths, not in phase with one another. Light waves generated by a laser are all of the same wavelength, occur at the same time and all are in step with one another.

Directional

Light from non-laser sources radiates away from the source in all directions. This divergence makes these sources useful for lighting homes and work places. Conversely, laser light diverges very slowly as it radiates away from the source, is concentrated into a narrow cone of divergence, and propagates outward in a single direction from the source.

Radiance

Radiance is closely related to the directional characteristic of a laser and describes the amount of power radiated by the laser within a narrow cone of divergence. This allows laser light to be focused with a lens, down to a very small and intense spot.

Ultraviolet (100 to 400 nm) consists of wavelengths shorter than the visible portion of the electromagnetic spectrum. The ultraviolet range is subdivided into near ultraviolet (UV-A) and far ultraviolet (UV-B, UV-C).

Visible (400 to 700 nm) consists of wavelengths ranging from the blue to the red portion of the

electromagnetic spectrum.

Infrared (700- 106 nm) consists of wavelengths which are longer than the visible portion of the

electromagnetic spectrum and terminates where the radio frequency portion begins. The infrared region is subdivided into near infrared (IR-A) and far infrared (IR-B, IR-C).

Types of Lasers

There are various types of lasers with differentiation based on active medium,excitation or pumping method, and characteristics of the output beam. Some general types are:

Solid Crystal

Solid Crystal Lasers employ a solid crystalline material as an active medium, such as Ruby (crystalline Aluminum oxide doped with Chromium) or Neodymium: YAG (triply ionized Neodymium doped with Yttrium Aluminum Garnet.). The optical cavity is a cylindrical rod with ends cut plane-parallel to each other then polished. These polished ends function as the reflecting and partially reflecting mirrors.

Gas

Gas Lasers use gas or a gas mixture, such as Argon or Helium-Neon, as an active medium and are

contained within a sealed glass tube called a plasma tube. Mirrors are either attached to the ends of the plasma tube or are mounted externally.

The pumping method is usually DC discharge within the plasma tube.

Gas lasers may be either continuous wave or pulsed with emitted wavelengths in the visible and infrared portions of the electromagnetic spectrum.

Liquid

Liquid Lasers typically use organic dyes in alcohol solutions (e.g., Rhodamine 6G), which are fed into a reaction chamber. The mirrors are mounted externally to the reaction chamber. The output wavelength can be varied by changing the concentration of dye fed into the reaction chamber.

Liquid lasers commonly use optical pumping (both from a flashtube or another laser), although chemical pumping is also employed.

Liquid lasers can be either pulsed or continuous wave, with emitted wavelengths covering the ultraviolet, visible and infrared portions of the electromagnetic spectrum.

Semiconductor

Semiconductor Lasers, which are also called laser diodes or injection lasers, employ an active medium that is a p-n junction between slabs of semi-conductor material (e.g., Gallium/Arsenic). The feedback mechanism is provided by cleaving sides of the slab along crystal planes to form parallel mirror surfaces.

The pumping method is by application of a power supply across the p-n junction with the intensity of light controlled by varying the power applied. The output is generally in the infrared end of the

electromagnetic spectrum.

Free-Electron Laser

The free-electron laser is similar in many respects to a microwave oscillator tube. The photon emission occurs between continuum states of free electrons. The transition wavelength is determined by momentum conservation in the interaction with an “undulation” magnet. The undulation magnet consists of a transverse magnetic field which varies sinusoidal along the electronic beam trajectory. An electron trans-versing such a magnet is free to scatter a virtual photon from the magnet

Click the following link to download about laser safety PPT and TBT

Laser safety - Power point presentation