Hazardous Communication:

Over view:

In order to ensure chemical safety in the workplace, information must be available about the identities and hazards of the chemicals. OSHA's Hazard Communication Standard (HCS) requires the development and dissemination of such information:

Chemical manufacturers and importers are required to evaluate the hazards of the chemicals they produce or import, and Prepare labels and material safety data sheets (MSDSs) to convey the hazard information to their downstream customers.

All employers with hazardous chemicals in their workplaces must have labels and MSDSs for their exposed workers, and train them to handle the chemicals appropriately.

Written Hazard Communication Program:

A written hazard communication program ensures that all employers receive the information they need to inform and train their employees properly and to design and put in place employee protection programs. It also provides necessary hazard information to employees, so they can participate in, and support, the protective measures in place at their workplaces. Employers therefore must develop, implement, and maintain at the workplace a written, comprehensive hazard communication program that includes provisions for container labeling, collection and availability of material safety data sheets, and an employee training program.

It also must contain a list of the hazardous chemicals, the means the employer will use to inform employees of the hazards of non-routine tasks (for example, the cleaning of reactor vessels), and the hazards associated with chemicals in unlabeled pipes. If the workplace has multiple employers onsite (for example, a construction site), the rule requires these employers to ensure that information regarding hazards and protective measures be made available to the other employers onsite, where appropriate. In addition, all covered employers must have a written hazard communication program to get hazard information to their employees through labels on containers, MSDSs, and training. The written program does not have to be lengthy or complicated, and some employers may be able to rely on existing hazard communication programs to comply with the above requirements. The written program must be available to employees, their designated representatives, OSHA and NIOSH.

SDS Information:

Safety Data Sheets

A Safety Data Sheet, often referred to by its acronym SDS, is a detailed informational document prepared by the manufacturer or importer of a hazardous chemical which describes the physical and chemical properties of the product. Information included in a Safety Data Sheet aids in the selection of safe products, helps employers and employees understand the potential health and physical hazards of a chemical and describes how to respond effectively to exposure situations. The format of a Safety Data Sheet may vary but there is specific information that must be included in each sheet. It is useful to review this information to increase your ability to use a Safety Data Sheet.

All Safety Data Sheets should include the following information:

• Section 1: Chemical Product & Company Information - Provides the chemical name on the label to the SDS. Also listed is the name, address and the phone number of the company, manufacturer or distributor who provides the chemical.

• Section 2: Composition & Ingredients - Identifies all hazardous ingredients, OSHA permissible exposure limits (PEL) & ACGIH (American Conference of Governmental Industrial Hygienists) Threshold Limit Values (TLVs).

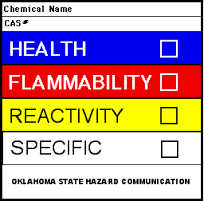

• Section 3: Hazard Identification - Information about the health effects of exposure. Description of the appearance, potential symptoms & health effects, routes of entry & target organs.

• Section 4: First Aid - Provides first aid procedures for each route of entry.

• Section 5: Fire-Fighting - Information on the explosive & fire properties, extinguishing agents and items and general fire-fighting information.

• Section 6: Accidental Release - Information on spill response, containment and required spill response PPE.

• Section 7: Handling and Storage - Information about chemical storage & handling and measures to prevent over-exposure.

• Section 8: Exposure Controls & Personal Protection - Engineering controls & personal protective equipment to reduce chemical exposure.

• Section 9: Physical & Chemical Properties - This section tells about the physical and chemical properties of the chemical. Characteristics include appearance, odor, physical state, pH, vapor pressure, vapor density, boiling point, freezing/melting point, solubility in water and specific gravity or density.

• Section 10: Stability & Reactivity - All potentially hazardous chemical reactions are identified in this section. Includes information on chemical stability, conditions to avoid, incompatibility, hazardous decomposition and hazardous polymerization.

• Section 11: Toxicological Information - Provides information such as acute data, carcinogen potential, reproductive effects, target organ effects, and other physiological aspects .

• Section 12: Ecological Information - Information concerning the environmental impact if a chemical is released into the environment.

• Section 13: Disposal Considerations - Information concerning proper chemical disposal, recycling and reclamation.

• Section 14: Transport Information - Shipping information includes the hazardous s description, hazard class and the identification number (UN or NA numbers).

• Section 15: Regulatory Information - Provides information about applicable federal regulations. Examples include OSHA, TSCA (Toxic Substance Control Act), CERCLA (Comprehensive Environmental Response, Compensation, and Liability Act), SARA Title III (Superfund Amendments and Reauthorization Act).

• Section 16: Additional Information - Provides other information about the chemical such as hazard ratings, preparation and revisions of the SDS, and label information.

Responsibilities:

Management:

- Ensure compliance with this program.

- Conduct immediate corrective action for deficiencies found in the program.

- Maintain an effective Hazard Communication training program.

- Make this plan available to employees or their designated representative.

Safety Manager:

- Maintain a list of hazardous chemicals using the identity that is referenced on the MSDS.

- Monitor the effectiveness of the program.

- Conduct annual audit of the program.

- Monitor employee training to ensure effectiveness.

- Keep management informed of necessary changes.

- Ensure MSDSs are available as required.

- Monitor facility for proper use, storage and labeling of chemicalsCompany Nurse.

- Ensure MSDS are available for emergency medical personnel when treating exposed employees.

- Provide information, as requested, concerning health effects and exposure symptoms listed on MSDSsSupervisors.

- Comply with all specific requirements of the program.

- Provide specific chemical safety training for assigned employees.

- Ensure chemicals are properly used stored & labeled.

- Ensure only the minimum amount necessary is kept at work stations.

- Ensure up to date MSDS are readily accessible to all employees on all shifts.

Employees:

- Comply with chemical safety requirements of this program.

- Report any problems with storage or use of chemicals.

- Immediately report spills of suspected spills of chemicals.

- Use only those chemicals for which they have been trained.

- Use chemicals only for specific assigned tasks in the proper manner.

The following general safety rules shall be observed when working with chemicals:

- Read and understand the Material Safety Data Sheets.

- Keep the work area clean and orderly.

- Use the necessary safety equipment.

- Carefully label every container with the identity of its contents and appropriate hazard warnings.

- Store incompatible chemicals in separate areas.

- Substitute less toxic materials whenever possible.

- Limit the volume of volatile or flammable material to the minimum needed for short operation periods.

- Provide means of containing the material if equipment or containers should break or spill their contents.

Chemical Storage

The separation of chemicals (solids or liquids) during storage is necessary to reduce the possibility of unwanted chemical reactions caused by accidental mixing. Explosives should be stored separately outdoors.Use either distance or barriers (e.g., trays) to isolate chemicals into the following groups:

- Flammable Liquids: store in approved flammable storage lockers.

- Acids: treat as flammable liquids.

- Bases: do not store bases with acids or any other material.

- Other liquids: ensure other liquids are not incompatible with any other chemical in the same storage location.

- Lips, strips, or bars are to be installed across the width of storage shelves to restrain the chemicals in case of earthquake.Chemicals will not be stored in the same refrigerator used for food storage. Refrigerators used for storing chemicals must be appropriately identified by a label on the door.

Container Labels:

It is extremely important that all containers of chemicals are properly labeled. This includes every type of container from a 5000 gallon storage tank to a spray bottle of degreaser. The following requirements apply:

- All containers will have the appropriate label, tag or marking prominently displayed that indicates the identity, safety and health hazards.

- Portable containers which contain a small amount of chemical need not be labeled if they are used immediately that shift, but must be under the strict control of the employee using the product.

- All warning labels, tags, etc., must be maintained in a legible condition and not be defaced. Facility weekly supervisor inspections will check for compliance of this rule.

- Incoming chemicals are to be checked for proper labeling.

Emergencies and Spills:

In case of an emergency, implement the proper Emergency Action Plan

1. Evacuate people from the area.

2. Isolate the area.

3. If the material is flammable, turn off ignition and heat sources.

4. Only personnel specifically trained in emergency response are permitted to participate in chemical emergency procedures beyond those required to evacuate the area.

5. Call for Emergency Response Team assistance if required.

Housekeeping:

1. Maintain the smallest possible inventory of chemicals to meet immediate needs.

2. Periodically review stock of chemicals on hand.

3. Ensure that storage areas, or equipment containing large quantities of chemicals, are secure from accidental spills.

4. Rinse emptied bottles that contain acids or inflammable solvents before disposal.

5. Recycle unused laboratory chemicals wherever possible.

6. DO NOT Place hazardous chemicals in salvage or garbage receptacles.

7. DO NOT Pour chemicals onto the ground.

8. DO NOT Dispose of chemicals through the storm drain system.

9. DO NOT Dispose of highly toxic, malodorous chemicals down sinks or sewer drains.

Chemical Protection Equipment Glove Selection Chart:

Selecting the proper chemical protection glove is a process that requires examining both the chemicals used, the processes and exposure times. Not all "rubber" type chemical protection gloves are the same. You cannot determine the applicability of a specific chemical protective glove without knowing the exact material and the materials resistance to decomposition for specific chemicals. S - Superior

E - Excellent

G - Good

F - Fair

NR - Not Recommended

*Not recommended for Acetaldehyde, use Butyl Rubber

Globally Harmonized System (GHS):

The CLP (classification, labeling and packaging) (Globally Harmonized System of Classification and Labeling of Chemicals), a United Nations system to identify hazardous chemicals and to inform users about these hazards. GHS has been adopted by many countries, including the U.S., around the world and is now also used as the basis for international and national transport regulations for dangerous goods.

The hazards of chemicals are communicated through standard statements and pictograms on labels and safety data sheets.

New terms have replaced old ones::

- mixtures for preparations .

- hazardous for dangerous.

- pictograms for symbols.

- hazard statements for risk phrases.

- precautionary statements for safety phrases.

- signal Words (e.g. Danger, Warning) replace the Indications of Danger New red-framed pictograms gradually replace the familiar orange danger symbols

HS Classification:

In most of the cases, suppliers need to decide on the classification of a substance or mixture. This is called self-classification.

In some cases, the decision on the classification of a chemical is taken at Community level to ensure an adequate risk management. These are usually the most hazardous substances: carcinogenic, mutagenic, toxic for reproduction or respiratory sensitisers, biocidal or plant protection products.

All previously harmonised substances classifications under the previous legislation (Dangerous Substances Directive) have been converted into CLP harmonised classifications. It is mandatory for the suppliers to apply this harmonised classification and labelling.

Key points:

- Look out for new labels and safety data sheets (SDS).

- Train workers to understand and recognise the new label information.

- Check that your use of the substance or mixture is covered on the SDS and is not advised against.

- Follow the advice provided on the new labels and in safety data sheets.

- Check whether the classification has changed .

- Evaluate the risks to workers and update your workplace risk assessments if necessary .

- If you are an employer, communicate these changes to your workers .

- If you have any questions about the new label or safety data sheet, speak to your supplier.

Click the below link to downloads more in Hazardous Communications

Hazardous Communication -Safety check sheet

Hazardous Communication -Tool Box

Hazardous Communication - OSHA Quick cards

Hazardous Communication Labels - OSHA Quick cards