E- Waste safety:

Introduction:

The definition of e-waste is essential to Step as an organization as well as its activities and its contributions to the world-wide solution of the e-waste problem. There is global inconsistency in the under-standing and application of the term “e-waste” in both legislation and everyday use. This has resulted in many definitions contained within e-waste regulations, policies and guidelines. The intent of this paper is to provide a non-legal definition of the term and clarity about how the term should be used.

E-waste is one of the fastest growing waste streams globally.The UNU ADDRESS project documents that e-waste volume placed on the market since 1990 has grown from 19.5 million tonnes to 57.4 million tonnes in 2010 and is set to more than tri-ple to approximately 75 million tonnes by 20151.

E-waste contains hazardous substances that, if treated inappropriately at end-of-life, can damage human health and the environment. It also contains complex valuable materials, such as precious metals which need to be treated properly to effectively recover them with minimal environmental impact.

Overview:

Industrial revolution followed by the advances in information technology during the last century has radically changed people's lifestyle. Although this development has helped the human race,

These days computer has become most common and widely used gadget in all kinds of activities ranging from schools, residences, offices to manufacturing industries. E-toxic components in computers could be summarized as circuit boards containing heavy metals like lead & cadmium; batteries containing cadmium; cathode ray tubes with lead oxide & barium; brominated flame retardants used on printed circuit boards, cables and plastic casing; poly vinyl chloride (PVC) coated copper cables and plastic computer casings that release highly toxic dioxins & furans when burnt to recover valuable metals; mercury switches; mercury in flat screens; poly chlorinated biphenyl's (PCB's) present in older capacitors; transformers; etc. Basel Action Network (BAN) estimates that the 500 million computers in the world contain 2.87 billion kgs of plastics, 716.7 million kgs of lead and 286,700 kgs of mercury. The average 14-inch monitor uses a tube that contains an estimated 2.5 to 4 kgs of lead. The lead can seep into the ground water from landfills thereby contaminating it. If the tube is crushed and burned, it emits toxic fumes into the air.

Definition of E-waste:

The term “e-waste” itself is self-explanatory, in the sense that it is an abbreviation of “electronic waste”. A key part of the definition is the word “waste” and what it logically implies – that the item has no further use and is rejected as useless or excess to the owner in its current condition. The definition of e-waste that has been agreed by Step is:

“E-Waste is a term used to cover items of all types of electrical and electronic equipment (EEE) and its parts that have been discarded by the owner as waste without the intention of re-use.”

It is important to note that the definition includes all types of EEE, as there is no room for regional variance or preference in a global definition; the fact that the item in question meets the definition “with circuitry or electrical components with power or battery supply”qualifies it for inclusion.

The inclusion of “parts” within the definition refers to parts that have been removed from EEE by disassembly and are electrical or electronic in nature.

The use of the term “discarded” is also central to this definition, meaning to throw away5 or get rid of as useless6. The term implies that the item in question is considered excess or waste by the owner. It is the critical point at which the potential nature of the item changes from a useful product to that of waste.

Effects on environment and human health:

"E-waste" is a popular, informal name for electronic products nearing the end of their "useful life. "E-wastes are considered dangerous, as certain components of some electronic products contain materials that are hazardous, depending on their condition and density. The hazardous content of these materials pose a threat to human health and environment.Discarded

- Computer,

- televisions

- VCRs

- stereos,

- copiers

- fax machines,

- electric lamps,

- cell phones,

- audio equipment and batteries

if improperly disposed can leach lead and other substances into soil and groundwater. Many of these products can be reused, refurbished, or recycled in an environmentally sound manner so that they are less harmful to the ecosystem.

Disposal of e-wastes is a particular problem faced in many regions across the globe. Computer wastes that are landfilled produces contaminated leachates which eventually pollute the groundwater. Acids and sludge obtained from melting computer chips, if disposed on the ground causes acidification of soil. For example, Guiyu, Hong Kong a thriving area of illegal e-waste recycling is facing acute water shortages due to the contamination of water resources.

This is due to disposal of recycling wastes such as acids, sludges etc. in rivers. Now water is being transported from faraway towns to cater to the demands of the population. Incineration of e-wastes can emit toxic fumes and gases, thereby polluting the surrounding air. Improperly monitored landfills can cause environmental hazards. Mercury will leach when certain electronic devices, such as circuit breakers are destroyed.The same is true for polychlorinated biphenyls (PCBs) from condensers. When brominated flame retardant plastic or cadmium containing plastics are landfilled, both polybrominated dlphenyl ethers (PBDE) and cadmium may leach into the soil and groundwater. It has been found that significant amounts of lead ion are dissolved from broken lead containing glass, such as the cone glass of cathode ray tubes, gets mixed with acid waters and are a common occurrence in landfills.

Not only does the leaching of mercury poses specific problems, the vaporization of metallic mercury and dimethylene mercury, both part of Waste Electrical and Electronic Equipment (WEEE) is also of concern. In addition, uncontrolled fires may arise at landfills and this could be a frequent occurrence in many countries. When exposed to fire, metals and other chemical substances, such as the extremely toxic dioxins and furans (TCDD tetrachloro dibenzo-dioxin, PCDDs-polychlorinated dibenzodioxins. PBDDs-polybrominated dibenzo-dioxin and PCDFspoly chlorinated dibenzo furans) from halogenated flame retardant products and PCB containing condensers can be emitted. The most dangerous form of burning e-waste is the open-air burning of plastics in order to recover copper and other metals. The toxic fall-out from open air burning affects both the local environment and broader global air currents, depositing highly toxic by products in many places throughout the world.

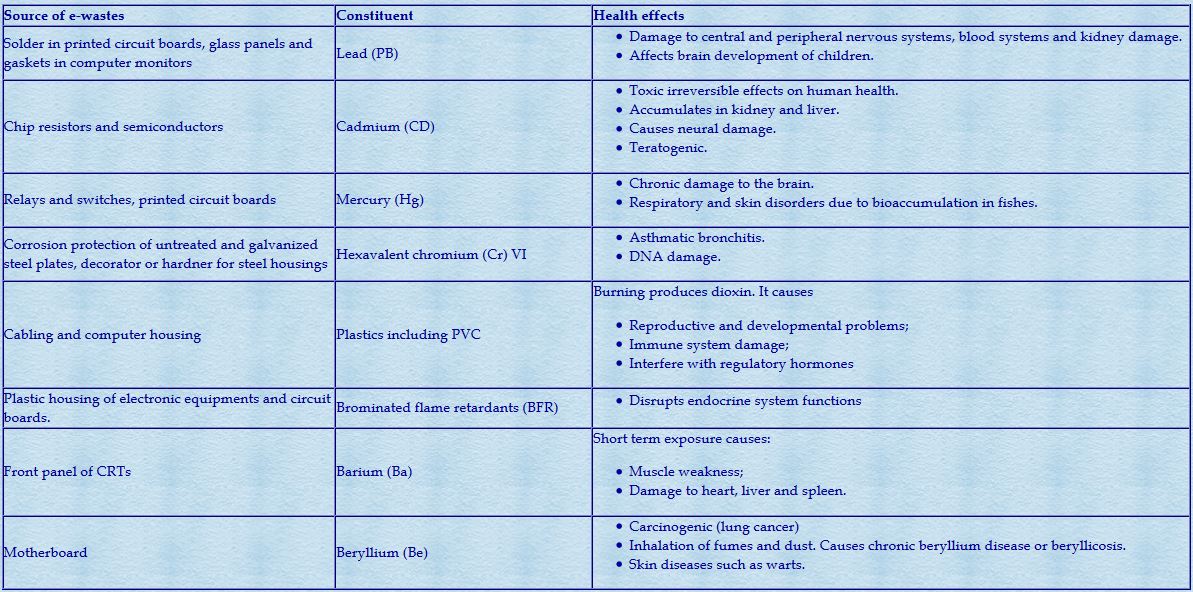

Table I summarizes the health effects of certain constituents in e-wastes. If these electronic items are discarded with other household garbage, the toxic pose a threat to both health and vital components of the ecosystem. In view of the ill-effects of hazardous wastes to both environment and health, several countries exhorted the need for a global agreement to address the problems and challenges posed by hazardous waste.

Responsibility and Role of industries:

1. Generators of wastes should take responsibility to determine the output characteristics of wastes and if hazardous, should provide management options.

2. All personnel involved in handling e-waste in industries including those at the policy, management, control and operational levels, should be properly qualified and trained. Companies can adopt their own policies while handling.

e-wastes. Some are given below:

- Use label materials to assist in recycling (particularly plastics).

- Standardize components for easy disassembly.

- Re-evaluate 'cheap products' use, make product cycle 'cheap' and so that it

has no inherent value that would encourage a recycling infrastructure.

- Create computer components and peripherals of biodegradable materials.

- Utilize technology sharing particularly for manufacturing and de manufacturing.

- Encourage / promote / require green procurement for corporate buyers.

- Look at green packaging options.

3. Companies can and should adopt waste minimization techniques, which will make a significant reduction in the quantity of e-waste generated and thereby lessening the impact on the environment. It is a "reverse production" system that designs infrastructure to recover and reuse every material contained within e-wastes metals such as lead, copper, aluminum and gold, and various plastics, glass and wire. Such a "closed loop" manufacturing and recovery system offers a win-win situation for everyone, less of the Earth will be mined for raw materials, and groundwater will be protected, researchers explain.

4. Manufacturers, distributors, and retailers should undertake the responsibility of recycling/disposal of their own products.

5. Manufacturers of computer monitors, television sets and other electronic devices containing hazardous materials must be responsible for educating consumers and the general public regarding the potential threat to public health and the environment posed by their products. At minimum, all computer monitors, television sets and other electronic devices containing hazardous materials must be clearly labeled to identify environmental hazards and proper materials management.

Management of E-Wastes:

It is estimated that 75% of electronic items are stored due to uncertainty of how to manage it. These electronic junks lie unattended in houses, offices,warehouses etc.and normally mixed with household wastes, which are finally disposed off at landfills. This necessitates implementable management measures.

In industries management of e-waste should begin at the point of generation. This can be done by waste minimization techniques and by sustainable product design. Waste minimization in industries involves adopting:

- inventory management,

- production-process modification,

- volume reduction,

- recovery and reuse.

Inventory management:

Proper control over the materials used in the manufacturing process is an important way to reduce waste generation (Freeman, 1989). By reducing both the quantity of hazardous materials used in the process and the amount of excess raw materials in stock, the quantity of waste generated can be reduced. This can be done in two ways i.e. establishing material-purchase review and control procedures and inventory tracking system.

Developing review procedures for all material purchased is the first step in establishing an inventory management program. Procedures should require that all materials be approved prior to purchase. In the approval process all production materials are evaluated to examine if they contain hazardous constituents and whether alternative non-hazardous materials are available.

Another inventory management procedure for waste reduction is to ensure that only the needed quantity of a material is ordered. This will require the establishment of a strict inventory tracking system. Purchase procedures must be implemented which ensure that materials are ordered only on an as-needed basis and that only the amount needed for a specific period of time is ordered.

Production-process modification:

Changes can be made in the production process, which will reduce waste generation. This reduction can be accomplished by changing the materials used to make the product or by the more efficient use of input materials in the production process or both. Potential waste minimization techniques can be broken down into three categories:

i) Improved operating and maintenance procedures,

ii) Material change and

iii)Process-equipment modification.

Improvements in the operation and maintenance of process equipment can result in significant waste reduction. This can be accomplished by reviewing current operational procedures or lack of procedures and examination of the production process for ways to improve its efficiency. Instituting standard operation procedures can optimize the use of raw materials in the production process and reduce the potential for materials to be lost through leaks and spills. A strict maintenance program, which stresses corrective maintenance, can reduce waste generation caused by equipment failure. An employee-training program is a key element of any waste reduction program.

Training should include correct operating and handling procedures, proper equipment use, recommend maintenance and inspection schedules, correct process control specifications and proper management of waste materials.

Hazardous materials used in either a product formulation or a production process may be replaced with a less hazardous or non-hazardous material. This is a very widely used technique and is applicable to most manufacturing processes. Implementation of this waste reduction technique may require only some minor process adjustments or it may require extensive new process equipment. For example, a circuit board manufacturer can replace solvent-based product with water-based flux and simultaneously replace solvent vapor degreaser with detergent parts washer.

Volume reduction:

Volume reduction includes those techniques that remove the hazardous portion of a waste from a non-hazardous portion. These techniques are usually to reduce the volume, and thus the cost of disposing of a waste material. The techniques that can be used to reduce waste-stream volume can be divided into 2 general categories: source segregation and waste concentration. Segregation of wastes is in many cases a simple and economical technique for waste reduction. Wastes containing different types of metals can be treated separately so that the metal value in the sludge can be recovered. Concentration of a waste stream may increase the likelihood that the material can be recycled or reused. Methods include gravity and vacuum filtration, ultra filtration, reverse osmosis, freeze vaporization etc.

For example, an electronic component manufacturer can use compaction equipments to reduce volume of waste cathode ray-tube.

Recovery and reuse:

This technique could eliminate waste disposal costs, reduce raw material costs and provide income from a salable waste. Waste can be recovered on-site, or at an off-site recovery facility, or through inter industry exchange. A number of physical and chemical techniques are available to reclaim a waste material such as reverse osmosis, electrolysis, condensation, electrolytic recovery, filtration, centrifugation etc. For example, a printed-circuit board manufacturer can use electrolytic recovery to reclaim metals from copper and tin-lead plating bath.

However recycling of hazardous products has little environmental benefit if it simply moves the hazards into secondary products that eventually have to be disposed of.Unless the goal is redesign the product to use nonhazardous materials, such recycling is a false solution.

E -Waste-reduce, reuse, recycle:

Millions of tons of electronic waste is generated every year in all over the world and the amount increases with every new gadget, computer and smartphone that hits the market. In our quest to improve our lives through technology we are creating electronic waste at an unprecedented rate. In response, we have seen more attention focused on methods to reduce, reuse and recycle electronic waste.

- E-waste is the most rapidly growing segment of the municipal solid waste stream.

- E-waste contains many valuable, recoverable materials such as aluminum, copper, gold, silver, plastics, and ferrous metals. In order to conserve natural resources and the energy needed to produce new electronic equipment from virgin resources, electronic equipment can be refurbished, reused, and recycled instead of being landfilled.

- E-waste also contains toxic and hazardous materials including mercury, lead, cadmium, beryllium, chromium, and chemical flame retardants, which have the potential to leach into our soil and water.

What are the benefits and advantages of recycle e-waste?

- There are several!

- Conserves natural resources. Recycling recovers valuable materials from old electronics that can be used to make new products. As a result, we save energy, reduce pollution, reduce greenhouse gas emissions, and save resources by extracting fewer raw materials from the earth.

- Protects your surroundings. Safe recycling of outdated electronics promotes sound management of toxic chemicals such as lead and mercury.

- Helps others. Donating your used electronics benefits your community by passing on ready-to-use or refurbished equipment to those who need it.

- Create Jobs. e-cycling creates jobs for professional recyclers and refurbishers and creates new markets for the valuable components that are dismantled.

- Saves landfill space. E-waste is a growing waste stream. By recycling these items, landfill space is conserved.

Electronic waste management options hierarchy:

- Reuse of whole units: Reuse functioning electronic equipment by donating it to someone who can still use it.

- Repair/refurbishment/remanufacturing of units

- Recovery/reuse of functional peripherals or components

- Recycling of constituent materials: Recycle those components that cannot be repaired.

- Last. Responsible disposal of hazardous and non-hazardous waste in permitted landfills.

Think back for a minute at the procession of computers, TVs, cell phones, radios, game consoles and music players that have passed through your hands over the years. What about the endless stream of products such as vacuum cleaners, microwaves, hair dryers, electric toothbrushes, alarm clocks, lamps, lawn mowers and smoke detectors that have come in and out of your life?

These are just a few examples of devices that are part of the growing phenomenon known as e-waste. E-waste is the term used to describe discarded electronics and electrical products. In the past few decades, the world's demand for gadgetry has gone through the roof and, inevitably, more waste has started to accumulate. As the bustling economies of China and India modernize and follow more Western trends, the worldwide generation of e-waste has hit astronomical proportions.

So what happens to all that e-waste? E-waste contains a bonanza of toxic and hazardous components that, for the most part, are currently being shunted into landfills. Much of the remaining portion is exported to developing nations, where many laborers, working under unsafe, unregulated conditions, recycle this e-waste. The work these laborers do, while it does provide some raw materials that can be reused, comes with some serious consequences.

E-waste Regulations:

If you don't want to damage the environment, are you supposed to transform your storage closet into an electronics graveyard? Never fear, the slow but steady mechanisms of social consciousness have been grinding at this one for a while now, and movement is starting to happen. Input about e-waste regulations are coming from a number of fronts, including grassroots organizations, governing bodies and industrial leaders.

Many organizations have recognized the potential for e-waste dangers for years. However, the issue recently came to the forefront of media in 2002, when Basel Action Network's (BAN) documentary "Exporting Harm" was released. BAN works to reduce the harmful effects of exporting e-waste and promotes sustainable solutions to worldwide waste issues. So-called recyclers and scrap brokers were buying e-waste from developed regions throughout the world and dumping it in developing nations. In some parts of these countries, people were dismantling electronics on street corners, instead of in recycling facilities.

BASEL CONVENTION:

The fundamental aims of the Basel Convention are the control and reduction of transboundary movements of hazardous and other wastes including the prevention and minimization of their generation, the environmentally sound management of such wastes and the active promotion of the transfer and use of technologies.

A Draft Strategic Plan has been proposed for the implementation of the Basel Convention. The Draft Strategic Plan takes into account existing regional plans, programmes or strategies, the decisions of the Conference of the Parties and its subsidiary bodies, ongoing project activities and process of international environmental governance and sustainable development. The Draft requires action at all levels of society: training, information, communication, methodological tools, capacity building with financial support, transfer of know-how, knowledge and sound, proven cleaner technologies and processes to assist in the concrete implementation of the Basel Declaration. It also calls for the effective involvement and coordination by all concerned stakeholders as essential for achieving the aims of the Basel Declaration within the approach of common but differentiated responsibility.

Electronic Waste:

Recycling laptops, computers and other electronic equipment:

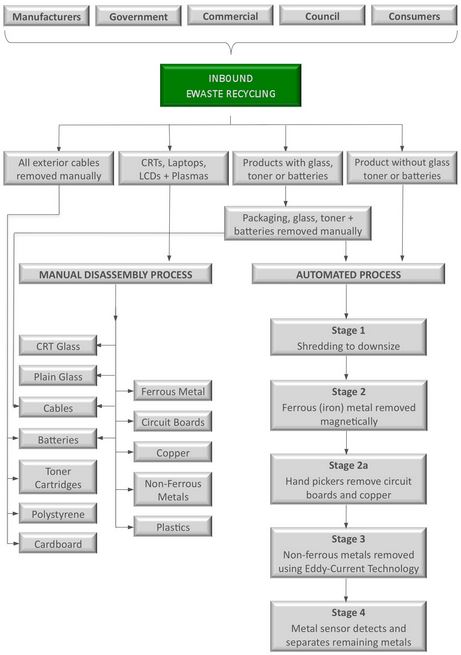

Most electronic waste goes through a recycling system called a WEEE (Waste Electrical and Electronic Equipment), which not only recycles 95-98%, by weight, of all ewaste passed through it, but ensures that any data left on hard drives and memories are thoroughly destroyed too.

- Picking Shed – first all the items are sorted by hand and batteries and copper are extracted for quality control.

- Initial Size Reduction Process – items are shredded into pieces as small as 100mm to prepare the ewaste to be thoroughly sorted. This is also where the data destruction takes place.

- Secondary Size Reduction – the small debris is shaken to ensure that it is evenly spread out on the conveyor belt, before it gets broken down even more. Any dust extracted is disposed of in an environmentally friendly way.

- Overband Magnet – using magnets, steel and iron are removed from the debris.

- Metallic & Non-Metallic Content – aluminium, copper and brass are separated from the non-metallic content. The metallic can then be reused and resold as raw materials.

- Water Separation – water is used to separate plastic from the glass content. Once divided all raw materials can then be resold.

Cathode Ray Tubes – recycling CRT Monitors and Televisions:

Recycling Cathode Ray Tubes, most commonly found in computer monitors and old televisions, is more complicated than recycling most electronic waste. This is because toxins found within CRT’s are among the most dangerous – CRT’s have lead in the glass which can seriously harm the environment and our health if leaked into soil and water systems.

- Separation of Monitor Body and Cathode Ray Tube – firstly the front of the monitor is removed so that the tube can be removed from within. The shell is then recycled along with regular ewaste.

- Size reduction process – The tubes and screens are shredded down into small pieces. Any glass dust created in this process is disposed of carefully, in an environmentally friendly way.

- Metal Removal – the broken bits of glass are then passed under magnets, where iron and steel is extracted from the glass material. The remaining material is then passed through Eddy Currents, which removes any aluminium and copper. These materials are then collected and reused as raw materials.

- Washing Line – The remaining glass is then cleared of oxides, phosphors and dust extracts, leaving just clean glass to be sorted.

- Glass Sorting Line – the final stage of CRT recycling sorts the leaded glass from the unleaded glass. These can then both be used in the creation of new screens, which is called closed loop recycling.

Recycling your electronic waste in this way might not be free, but it’s a small price to pay to avoid sending these toxic materials to landfill, polluting the environment for future generations – especially when they can so easily be recycled.

Do’s & Don’t:

Do’s:

- All electrical and electronic products are required to be handed over only to the Authorized recycler.

- The product should be handed over only to authorized recycler for disposal.

- Keep the product in isolated area, after it becomes non-functional /un- repairable so as to prevent its accidental breakage.

Don’ts:

- The product should not be opened by the User himself / herself, but only by authorised service personnel.

- The product is not meant for re-sale any unauthorised agencies/scrap dealer/kabariwalahs.

- The product is not meant for mixing into household waste stream.

- Do not keep any replaced spare part(s) from the pro duct in exposed area.

- Do Not Dispose Off The E-WASTE In Landfills

Click the below link to downloads the E-Waste documents

Power Point Presentation - E-Waste

Power Point Presentation - E waste management rules-2011

Recycling work place guidelines - E waste

E - Waste recycling process

E- Waste