Corrosive materials:

Corrosives are materials that can attack and chemically destroy exposed body tissues. Corrosives can also damage or even destroy metal. They begin to cause damage as soon as they touch the skin, eyes, respiratory tract, digestive tract, or the metal. They might be hazardous in other ways too, depending on the particular corrosive material.

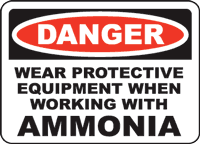

Most corrosives are either acids or bases. Common acids include hydrochloric acid, sulfuric acid, nitric acid, chromium acid, acetic acid and hydrofluoric acid. Common bases are ammonium hydroxide, potassium hydroxide (caustic potash) and sodium hydroxide (caustic soda).

Other chemicals can be corrosive too. Check the supplier labels on chemical product containers.

It is wise to treat unknown materials as very hazardous until they are positively identified.

Corrosive materials are present in almost every workplace. Acids, bases (which include caustics or alkalis), and other chemicals may be corrosive. Everyone who works with corrosives must be aware of their hazards and how to work safely with them.

corrosives hazardous to my health?

Corrosives can burn and destroy body tissues on contact. The stronger, or more concentrated, the corrosive material is and the longer it touches the body, the worse the injuries will be.

Some corrosives are toxic and can cause other health problems. Check the MSDS and label on the container for warnings of other possible health effects.

An example is the chemical glutaraldehyde. It has been used as a disinfectant and sterilizing agent in medical and dental settings as well as other uses. It is harmful if inhaled or swallowed. Glutaraldehyde can be irritating or corrosive to the respiratory tract, eyes and skin. It may cause permanent eye injury. It is also a skin sensitizer as it may cause (severe) allergic skin reactions.

hazards associated with corrosives:

Some corrosives are also flammable or combustible and can easily catch fire and burn or explode.

Some corrosives are incompatible with other chemicals. They may undergo dangerous chemical reactions and give off toxic or explosive products if they contact each other.

The MSDSs and the labels on the containers should explain all of the hazards for the corrosive materials that you work with.

hazardous to my eyes:

Corrosive materials can severely irritate, or in come cases, burn the eyes. This could result in scars or permanent blindness. The stronger, or more concentrated, the corrosive material is and the longer it touches the eyes, the worse the injury will be.

hazardous to my skin:

Corrosives touching the skin can severely irritate or even badly burn and blister the skin. Severe corrosive burns over a large part of the body can cause death.

hazardous when I breathe them in:

Breathing in corrosive vapours or particles irritates and burns the inner lining of the nose, throat, windpipe and lungs. In serious cases, this results in pulmonary edema, a buildup of fluid in the lungs that can be fatal.

hazardous when corrosives touch metals:

Many corrosives attack and corrode metals. Contact with corrosives can damage containers, equipment, installations and building components made from unsuitable materials. The rate of metal corrosion is greater when the corrosive is stronger and the temperature is higher. When acids attack metals, hydrogen gas is often given off. This is a flammable gas which can burn or explode if an ignition source is present.

Common bases, such as sodium hydroxide and potassium hydroxide, can also attack some metals like aluminum, zinc, galvanized metal, and tin to produce hydrogen gas. The MSDS for a particular corrosive should explain which metals or other materials, such as plastics or wood, it will attack.

Ventilation wherever corrosives are present:

Well-designed and well-maintained ventilation systems remove corrosive vapours, fumes, mists or airborne dusts from the workplace and reduce their hazards.

The amount and type of ventilation needed to minimize the hazards of airborne corrosives depends on such things as the kind of job, the kind and amount of materials used, and the size and layout of the work area. An assessment of the specific ways corrosives are stored, handled, used, and disposed of is the best way to find out if existing ventilation controls (and other hazard control methods) are adequate.

Some workplaces may need a complete system of hoods and ducts to provide acceptable ventilation. Others may require a single, well-placed exhaust fan. Use corrosion-resistant construction in ventilation systems for corrosive materials. No special ventilation system may be needed when working with small amounts of corrosives which do not give off airborne contaminants.

Storage of corrosives:

In general, store corrosives separately, away from processing and handling areas, and from other materials. Separate storage can reduce the amount of damage caused in case of fires, spills or leaks. If totally separate storage is not possible, store corrosives away from incompatible materials.

Some corrosives are incompatible with each other. For example, acids and bases react together, sometimes violently. Do not store them beside each other.

Walls, floors and shelving in corrosive storage areas should be made from materials that resist attack by corrosives. Floors in areas where liquid corrosives are stored should not allow liquids to penetrate. Since many corrosive liquids flow easily, store them in corrosion-resistant trays to contain spills or leaks. For large containers, such as 250-litre (55-gallon) drums, provide dikes around liquid storage areas and sills or ramps at door openings.

Store containers at a convenient height for handling, below eye level if possible. High shelving increases the risk of dropping containers and the severity of damage if a fall occurs.

Store corrosives in areas which are:

- Well ventilated.

- Supplied with adequate firefighting equipment.

- Supplied with suitable spill clean-up equipment and materials.

- Labelled with proper warning signs.

At all times:

- Allow only trained, authorized people into storage areas.

- Keep the amount of corrosive material in storage as small as possible.

- Inspect storage areas regularly for any deficiencies, including corrosion damage, leaking containers, or poor housekeeping. Correct all deficiencies as soon as possible.

Storage temperature important:

Store corrosives in dry, cool areas, out of direct sunlight and away from steam pipes, boilers or other sources of heat. If a sealed full drum or carboy of a corrosive liquid is stored in direct sunlight or near other heat sources, vapor levels in the container can build up. This leads to an increase in pressure in the container. In severe cases, this could cause the container to rupture. A buildup of pressure might also result in the material shooting out into the face of the person opening the container.

Follow the chemical manufacturer's or supplier's recommendations for storage temperature. Where appropriate, store corrosive liquids at temperatures above their freezing (melting) points. Acetic acid, for example, has a freezing point of approximately 17°C (63°F) and can freeze in an unheated room. As it freezes, it expands and can crack a glass container.

Avoid rapid temperature changes in corrosive liquid storage areas. If a tightly-sealed corrosive liquid container is cooled suddenly, a partial vacuum could form inside it. In extreme cases, the container might collapse and leak.

Handling corrosive materials carefully:

Take care when dispensing or transferring corrosives from one container to another. Dispense from only one container at a time. Finish all the dispensing of one material before starting to dispense another. Be sure containers are closed after dispensing.

Handle corrosives so that dusts, mists, vapours, or fumes do not get into the air. Be very careful when transferring from larger containers into smaller ones. Many injuries have been caused by spillage from open, unstable, or breakable containers during material transfer.

If liquid corrosives are stored in drums, use a corrosion-resistant drum pump for transferring liquids into other containers. Pumps are also available for dispensing corrosive liquids from most sizes and types of the supplied containers. Do not transfer liquids by pressurizing their usual shipping containers with air or inert gas. Ordinary drums and barrels may be damaged by the pressure. Never pipette corrosive liquids by mouth. Use a pipette bulb or aspirator instead. Transfer corrosive solids using tools like scoops or shovels that are corrosion resistant.

Dispose of waste material safely:

Corrosive wastes are hazardous and must always be handled safely.

All containers for corrosive wastes must be made from corrosion-resistant materials. Identify the contents of these containers with suitable labels.

"Empty" drums, bottles and other containers often have hazardous corrosive residues inside them. Never use these "empty" containers for anything else, no matter how clean they seem to be. Treat them as corrosive wastes. It may be possible to safely decontaminate "empty" containers. The chemical manufacturer or supplier can give advice about this.

Never dispose of corrosives down sinks or drains that connect to sanitary or storm sewers. Dispose of them according to the manufacturer's or supplier's directions, or through hazardous waste collection and disposal companies. In all cases, dispose of corrosive wastes according to the environmental laws that apply to your jurisdiction. Contact the appropriate environmental officials for details about the disposal laws that apply for specific corrosives.

Good housekeeping, personal cleanliness and maintain equipment?

Good housekeeping, personal cleanliness and equipment maintenance are important wherever any chemicals, including corrosives, are used.

Maintain cleanliness and order at all times in the workplace:

- Clean up any spills and buildups of corrosives promptly and safely.

- Properly dispose of unlabelled or contaminated chemicals.

- Remove empty containers at once from work areas.

- Ensure that all containers for waste are properly marked and easily located.

Personal cleanliness is a very important way of protecting personnel working with hazardous chemicals.

- Wash hands before eating, drinking, smoking or going to the toilet.

- Remove and clean contaminated clothing before wearing it again, or discard it.

- Do not smoke, drink, chew gum or eat in any areas where hazardous chemicals are present.

- Store food and tobacco products in uncontaminated areas.

- Avoid touching yourself with contaminated hands.

- Clean yourself thoroughly at the end of the workday.

Regular maintenance of equipment is important in preventing leaks or emissions of corrosives into the workplace.

- Ensure maintenance personnel know the possible hazards of the materials they might be exposed to.

- Be sure they know any special procedures and precautions that might be needed before they begin to work on equipment.

Regular workplace inspections can help in spotting areas where health and safety problems may be developing.

Wear proper personal protective equipment:

If other methods, such as engineering controls, are not available or effective enough to control exposure to corrosives, wear suitable personal protective equipment (PPE). Choosing the right PPE to wear when doing a particular job is essential. MSDSs should provide general guidance. Selecting PPE for a specific job is best done with the help of someone who knows how to evaluate the hazards of the job and how to select the proper PPE.

Avoid Skin Contact

Wear protective gloves, aprons, boots, hoods, or other clothing depending on how much chance there is of skin contact. This clothing must be made of materials that resist penetration or damage by the chemical. The MSDS should recommend appropriate materials. If it does not, contact the chemical's manufacturer or supplier for specific information.

Protect Your Eyes and Face

Always wear eye protection when working with corrosives. Although ordinary safety glasses provide some protection, chemical safety goggles are best. In some cases, you should also wear a face shield (with safety glasses or goggles) to protect your face from splashes. The current CSA Standard Z94.3, "Eye and Face Protectors," provides advice on selection and use of eye and face protectors.

Avoid Breathing Corrosive Vapours, Fumes, Dusts or Mists

If respirators must be used for breathing protection, there should be a written respiratory protection program to follow. Guidance for developing a program can be found in the current CSA Standard Z94.4, "Selection, Care, and Use of Respirators." Follow all legal requirements for respirator use and approvals. These may vary between jurisdictions in Canada.

Know and be familiar with the right PPE for emergencies, as well as normal operations.

You must wear the PPE needed for doing a particular job. PPE cannot protect you if it is not worn.

Basic safety procedures concerning corrosives:

Following these basic safe practices will help protect you from the hazards of corrosive materials:

- Obtain and read the Material Safety Data Sheets (MSDSs) for all of the materials you work with.

- Be aware of all of the hazards (fire/explosion, health, chemical reactivity) of the materials you work with.

- Know which of the materials you work with are corrosives.

- Store corrosives in suitable labelled containers away from incompatible materials, in a cool, dry area.

- Store, handle, and use corrosives in well-ventilated areas.

- Inspect containers for damage or leaks before handling. Never use containers that appear to be swollen.

- Handle containers safely to avoid damaging them.

- Dispense corrosives carefully and keep containers closed when not in use.

- Stir corrosives slowly and carefully into cold water when the job requires mixing corrosives and water.

- Handle and dispose of corrosive wastes safely.

- Practice good housekeeping, personal cleanliness and equipment maintenance.

- Wear the proper personal protective equipment for each of the jobs you do.

- Know how to handle emergencies (fires, spills, personal injury) involving the corrosive materials you work with.

- Follow the health and safety rules that apply to your job.

- Flush contaminated eyes or skin with water for at least 20-30 minutes, sometimes longer, in case of accidental contact. Call immediately for medical assistance.

- Know where to closest eyewash station and safety showers are located, and how to use them.

- Never return unused material to the original container. It may contain traces of contamination which may cause a chemical reaction.

- Do not reuse empty containers -- the residue may be hazardous.

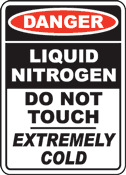

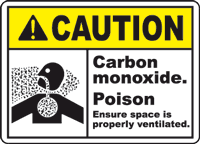

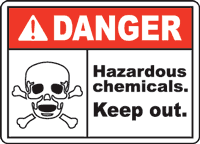

CHEMICAL IDENTIFICATION SIGNAGE

CHEMICAL STORAGE SIGNAGE

CHEMICAL WARNING SIGNAGE

Click the below link to download the corrosivematerials

Corrosive Materials Guidelines

Chemical Identification signage

Tool box talk - Hazardous Communication