Accident Prevention :

Workplace accident prevention plans and control of hazards is the result of a well designed and executed safety and health program. One of the keys to a successful program includes unbiased, prompt and accurate workplace accident investigations. The basic purpose of these investigations is to determine measures that can be taken to prevent similar accidents in the future. A comprehensive occupational Illness and Injury prevention plan can save money and lives.

Accident Investigation Techniques

An accident is any unplanned event that results in personal injury or in property damage. When the personal injury requires little or no treatment, it is minor. If it results in a fatality or in a permanent total, permanent partial, or temporary total (lost-time) disability, it is serious. Similarly, property damage may be minor or serious. Investigate all accidents regardless of the extent of injury or damage.

Workplace Accident Prevention

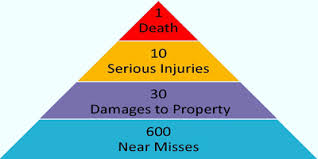

Accidents are usually complex. An accident may have 10 or more events that can be causes. A detailed analysis of an accident will normally reveal three cause levels: basic, indirect, and direct. At the lowest level, an accident results only when a person or object receives an amount of energy or hazardous material that cannot be absorbed safely. This energy or hazardous material is the DIRECT CAUSE of the accident. The direct cause is usually the result of one or more unsafe acts or unsafe conditions, or both. Unsafe acts and conditions are the INDIRECT CAUSES or symptoms. In turn, indirect causes are usually traceable to poor management policies and decisions, or to personal or environmental factors. These are the BASIC CAUSES. In spite of their complexity, most accidents are preventable by eliminating one or more causes.

Accident investigations determine not only what happened, but also how and why. The information gained from these investigations can prevent recurrence of similar or perhaps more disastrous accidents. Accident investigators are interested in each event as well as in the sequence of events that led to an accident. The accident type is also important to the investigator. The recurrence of accidents of a particular type or those with common causes shows areas needing special accident prevention emphasis. Most accidents are preventable by eliminating one or more causes. Accident investigations determine not only what happened, but also how and why. The information gained from these investigations can prevent recurrence of similar or perhaps more disastrous accidents. Accident investigators are interested in each event as well as in the sequence of events that led to an accident. The accident type is also important to the investigator. The recurrence of accidents of a particular type or those with common causes shows areas needing special accident prevention emphasis.

Accident Investigation

In general, experienced personnel should conduct interviews. All interviews should be conducted in a quite and private location. It is essential to get preliminary statements as soon as possible from all witnesses. Investigators should not provide any facts to the witness - only ask non-leading questions. Accidents represent problems that must be solved through investigations. Formal procedures are helpful in identifying and solving problems. This section discusses two of the most common procedures: Change Analysis and Job Safety Analysis.

Accident Fact Finding

Gather evidence from many sources during an investigation. Get information from witnesses and reports as well as by observation. Interview witnesses as soon as possible after an accident. Inspect the accident site before any changes occur. Take photographs and make sketches of the accident scene. Record all pertinent data on maps. Get copies of all reports. Documents containing normal operating procedures, flow diagrams, maintenance charts, or reports of difficulties or abnormalities are particularly useful. Keep complete and accurate notes in a bound notebook. Record pre-accident conditions, the accident sequence, and post-accident conditions. In addition, document the location of victims, witnesses, machinery, energy sources, and hazardous materials.

In some investigations, a particular physical or chemical law, principle, or property may explain a sequence of events. Include laws in the notes taken during the investigation or in the later analysis of data. In addition, gather data during the investigation that may lend itself to analysis by these laws, principles, or properties. An appendix in the final report can include an extended discussion.

After interviewing all witnesses, the team should analyze each witness' statement. They may wish to re-interview one or more witnesses to confirm or clarify key points. While there may be inconsistencies in witnesses' statements, investigators should assemble the available testimony into a logical order. Analyze this information along with data from the accident site.

Not all people react in the same manner to a particular stimulus. For example, a witness within close proximity to the accident may have an entirely different story from one who saw it at a distance. Some witnesses may also change their stories after they have discussed it with others. The reason for the change may be additional clues.

A witness who has had a traumatic experience may not be able to recall the details of the accident. A witness who has a vested interest in the results of the investigation may offer biased testimony. Finally, eyesight, hearing, reaction time, and the general condition of each witness may affect his or her powers of observation. A witness may omit entire sequences because of a failure to observe them or because their importance was not realized.

OSHA INJURY AND/OR ILLNESS INCIDENCE RATES-CALCULATOR

1.Determine the total number of hours worked and from your OSHA Record keeping logs determine the number of injuries and/or illnesses.

NOTE: Employee hours must reflect all full-time and part-time workers, including seasonal, temporary (including temporary contract workers if supervised by company personnel), administrative, supervisory, clerical, and overtime.

2. Calculate injury/illness rates

N = Number of Recordable Injuries and/or Illnesses in One Year

EH = Total Number of Hours Worked by all Employees in One Year

200,000 = Equivalent of 100 Full-Time Employees Working 40 Hour Weeks

50 Weeks Per Year

Incidence Rates are calculated (N/EH) x 200,000 =

Result Total Incidence Rate per year

3. Calculate lost work day incidents rates:

LWD = Number of Injuries and/or Illnesses Resulting in Lost Workdays or Restricted Work Activity

EH = Total Number of Hours Worked by all Employees in One Year

LWDI Rate = LWD cases x 200,000 / =

Employee Hours Worked

Result Lost Workday Incidence Rate per year

OSHA Incident rate calculators

Click here to download the documents in PDF

Click here to know more details and videos about accident case studies

Click here to download the hand book and empty form